- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In today’s fast-paced world of technology, the demand for smaller, more efficient electronic devices is ever-increasing. At the heart of these devices lies the printed circuit board (PCB), which serves as the foundation for electronic components. As applications become more compact and sophisticated, learning how to create smaller PCBs is essential for engineers and designers. In this blog, we will explore various strategies and techniques to achieve smaller PCB designs while maintaining performance and reliability.

The push for smaller PCBs is driven by several factors. First, consumers increasingly prefer compact devices that are portable and easy to use. Second, advancements in technology allow for greater functionality in smaller packages, which means that engineers need to rethink traditional designs. Lastly, smaller PCBs can lead to reduced material costs and improved energy efficiency, making them an attractive option for manufacturers.

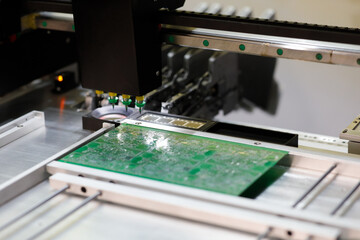

One of the most effective ways to minimize PCB size is to adopt surface-mount technology (SMT). Unlike through-hole components, which require leads to pass through the board, SMT components are soldered directly onto the surface. This not only saves space but also allows for denser layouts. Using SMT enables designers to choose smaller components, ultimately contributing to a more compact design.

A well-thought-out circuit design can significantly reduce PCB size. Start by simplifying the circuit: eliminate unnecessary components and choose integrated circuits (ICs) that perform multiple functions. For example, instead of using separate chips for processing, memory, and communication, opt for a single IC that integrates all these functions. This not only reduces the number of components but also shortens the connections needed between them.

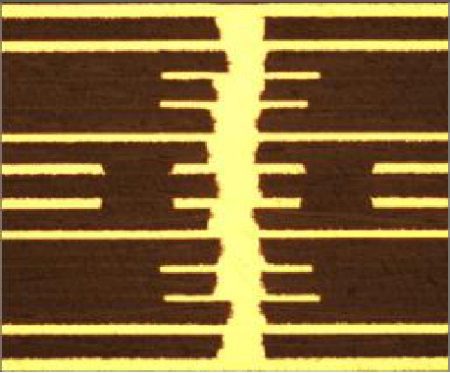

High-density interconnect (HDI) technology allows for a more compact design by utilizing finer lines and smaller vias. HDI PCBs can include buried and blind vias, which minimize space while enhancing signal integrity. By employing HDI techniques, designers can create more complex circuits in a smaller footprint, making this a valuable strategy for achieving smaller PCBs.

While multi-layer PCBs can seem counterintuitive for space-saving, they allow for more compact designs by stacking layers of circuitry. This vertical arrangement lets you route more connections within a smaller area. For example, a four-layer PCB can provide routing options that reduce the need for wide traces and large components, leading to a smaller overall size.

Effective component placement is key to achieving smaller PCBs. Group related components together to minimize trace lengths and avoid crossing signals. This can reduce electromagnetic interference (EMI) and enhance overall performance. Additionally, place high-frequency components away from sensitive areas to prevent signal degradation. Using software tools for PCB layout can help visualize and optimize component placement effectively.

Selecting the right materials can also contribute to smaller PCB designs. Advanced materials, such as flexible substrates, allow for innovative designs that can bend or conform to the device’s shape. This flexibility can save space in compact devices, such as wearables or medical devices, where traditional rigid PCBs may not fit.

As devices become smaller, managing heat dissipation becomes critical. Ensure that your design incorporates thermal management solutions, such as thermal vias or heat sinks. Efficient thermal design can prevent overheating and allow for higher component density without sacrificing reliability. This consideration is essential for compact designs where space is at a premium.

Prototyping is crucial when developing smaller PCBs. Rapid prototyping allows for testing various configurations and layouts before finalizing the design. Use tools like 3D modeling to visualize the board within the intended device. Iterative testing helps identify potential issues early, ensuring that the final product meets both size and performance requirements.

Creating smaller PCBs is a multifaceted challenge that requires careful planning and innovative design techniques. By leveraging surface-mount technology, optimizing circuit design, and implementing high-density interconnect strategies, engineers can achieve compact and efficient PCBs that meet the demands of modern electronics. As technology continues to evolve, the ability to create smaller, more functional PCBs will play a crucial role in the development of next-generation devices.

Embracing these strategies not only improves design efficiency but also enhances the user experience, ultimately leading to more successful products in a competitive marketplace. As the trend toward miniaturization continues, mastering the art of creating smaller PCBs will be essential for engineers and designers alike.

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve