- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

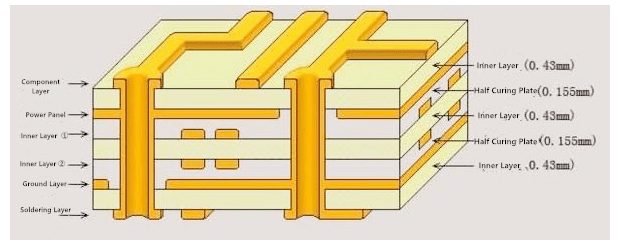

How to design a multilayer PCB board?

Multi-layer printed circuit board design technology is similar to double-sided PCB design, and the wiring is easier. First of all, you have to divide the layered structure. For easier designing, it is best to use the substrate as the center, symmetrically distributed to both sides, and the adjacent signal layers are electrically grounded. Secondly, ask the PCB manufacturer for the parameters (dielectric constant, line width, curium thickness, board thickness) for impedance matching. These parameters do not need to be calculated by themselves and should be provided by the PCB manufacturer. With these parameters, you can calculate the line width, line spacing, and line length, and then you can start PCB drawing. There are three types of hole connected multi-layer boards: blind holes, buried holes, and vias, which makes wiring job easily, but these connection methods are expensive. The high-speed line is best to place in the inner layer because the top and bottom layers are easily affected by outside temperature, humidity, and air. If you need to test, you can make a test via.

What are the advantages of multilayer PCB? Although single-layer circuit boards have their advantages, multi-layer designs are more advantageous for certain applications. If you want to know the advantages of multilayer PCB, you must understand what multilayer PCB is beforehand. Check it here. For some devices, it is necessary to use a multilayer PCB to meet the requirements. What are the benefits of more complex multilayer PCBs?

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve