- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

When I first studied electronics and circuit design, I often heard older engineers say that good engineers are also very good technicians. In other words, it is not enough to simply understand the performance goals of the board and create circuit layouts to achieve those goals. In addition, you must understand how and why boards are structured. Needless to say, I find this to be true, because if these issues are not taken into account during the design process, then many problems may arise during the manufacturing process.

One of the biggest problems or threats to PCBs during manufacture and operation is heat. Ironically, heat is an integral part of the manufacturing process, especially during assembly where components are soldered onto plates. In practice, for surface-mount technology, reflow furnaces are used, and the board is subjected to quite a long period of time.

Assessing the temperature the board will withstand is an aspect of good PCB design that requires an understanding of how heat is distributed and how the board’s temperature changes or thermal diffustivities are distributed. This parameter depends on the material of the board and its thickness, and is usually determined by the application of laser flash analysis (LFA). After first clearly defining the thermal diffussibility to be determined, let’s look at how to make an LSA for a PCB. We will then be prepared to propose a method for incorporating this thermal management into the design process.

Understand the thermal diffusivity of PCBA

Thermal management is usually not a major consideration unless dealing with high-power PCBs, where heat dissipation or heat dissipation is critical. This is really important; However, this is only one aspect of good thermal management. In order to get a better, more comprehensive view, it may be helpful to define some terms.

PCB Thermal Management Terms:

Heat dissipation is the process of removing excess heat from the circuit board. There are a number of technologies that can achieve this. Includes radiators using high-power components and geographically located heat sinks. Heat dissipation is the main heat dissipation problem during operation.

For PCB assembly, the temperature of the board must be raised. If lead-free solder is used, these temperatures may be approximately 250°C (482°F). In contrast to PCB operations, where the goal is to remove excess heat as quickly as possible, ensuring even distribution of heat during manufacturing is the goal of obtaining high quality solder joints.

Heat is always transferred from a higher temperature to a lower temperature unless forced or pumped artificially. Thermal diffusivity is the rate at which this transfer occurs on a circuit board.

From these definitions, we can see that the thermal diffusivity is an important parameter for dissipation during operation and distribution during manufacturing. Now, let’s look at how to determine this parameter for manufacturing.

Laser flash analysis for PCB fabrication

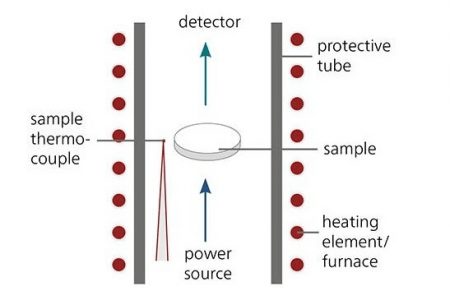

In the figure above, an example of the device used to perform LFA is shown. The example in the figure represents plates. The test is usually performed in a closed machine and the results are analyzed by software.

The parameter of concern is the thermal diffusivity, which can be determined using the following formula:

(1) α= K/(⍴c p)

α is the thermal diffusivity

K is the thermal conductivity,

⍴ is the material density,

cp is specific heat capacity.

All of the variables in the equation. It is related to temperature. This allows the determination of changes as the temperature rises. With this data, you can achieve accurate thermal analysis for your design, resulting in effective thermal management.

Laser flash analysis and design in PCBA manufacturing

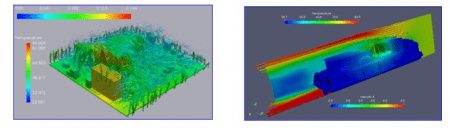

The results of the LSA can be used to ensure that selected board materials and PCB layouts are optimized for your manufacturing process. In addition, Cadence’s CELSIUS Thermal Solver can be used to complete the comprehensive Thermal management strategy including electrothermal co-simulation.

As shown above, the Celsius temperature allows you to assess the heat distribution of the board or combine it with electrical analysis to plan your cooling strategy.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve