- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

With the development of The Times, the progress of science and technology, electronic products are also changing with each passing day. In the field of electronic assembly technology, it is facing one test after another. Need to follow the development of electronic technology, under the condition of the people in the electronic assembly technology and sufficient power amplifier, bold innovation experiment and research and development, in this context a containing fine wires, using thin, soft polymer film made flexible circuit arises at the historic moment, it can complete the application of the surface mount technology, and bending and affect the normal work.

Today’s flexible electronics use SMT technology, which makes it possible to make very thin, very sophisticated circuits with insulation thickness of less than 25μm. These flexible circuits can be bent at will and rolled up into cylinders to take advantage of three-dimensional volume. It breaks the traditional fixed usage area mindset, thus forming the ability to make full use of the volume shape, which can significantly increase the effective use density of the conductor length used per unit area currently commonly used, resulting in a high-density assembly form.

In recent years, flexible circuit technology has been applied in various fields, such as radio communication, computer, and automotive electronic equipment. Unlike in the past, flexible circuits have been used as a substitute for rigid cables. They have been well developed as a substitute for rigid circuits and printed circuit boards in applications requiring thin or three-dimensional circuits. In order to meet the rigid and flexible application requirements, rigid and flexible technology in rigid circuit board combined with a flexible circuit, the flexible circuit board is the most widely used. The functions of flexible Circuit boards can be divided into four types: Lead lines, Printed circuits, connectors, and IntegraTIon of functions. Applications cover the computer, computer peripheral auxiliary systems, consumer electronics, and automobiles, etc.

Flexible circuit material: the fate of the film

Insulation film has the characteristics of flexibility, which can be used as the insulation carrier of the circuit board to form the base layer of the circuit. When choosing a flexible dielectric film, it is necessary to investigate and test the heat resistance, cladding performance, thickness, mechanical properties, and electrical properties of the material. The most commonly used materials are polyimide and polyester, which are usually commercially available. In the United States, nearly 80% of all flexible circuit manufacturers use polyimide film as flexible circuit material, and about 20% of manufacturers combine polyester film. Polyimide materials are non-flammable, geometrically stable, have high tear resistance, and can withstand high temperatures during welding.

Material of flexible circuit: adhesive sheet

The ability of the bonding sheet is to bond the film to the metal foil, as well as the bonding between the film and the film. The reinforcing ribs are bonded to the flexible circuit with adhesives, in order to provide mechanical support and eliminate stress when the components and connectors are inserted. It consists of two sides of the film coated with an adhesive. The adhesive sheet can provide environmental protection and electrical insulation, it can play the role of removing thin film and bonding in a few layers of multi-layer circuit. Different types of adhesive sheets can be used for different film substrates. For example, the adhesive sheets used for polyester and polyimide are different. The adhesive sheets used for polyimide substrate can be divided into epoxy and acrylic.

Material of flexible circuit: copper foil

Copper foil is a conductive layer covering the bonding on the insulation substrate, after selective etching to form a conductive line. The vast majority of copper foil is calendered copper foil or electrolytic copper foil. The ductility and bending resistance of calendered copper foil are better than that of electrolyzed copper foil. The elongation of calendered copper foil is 20%-45%, and the elongation of electrolyzed copper foil is 4%-40%. Copper foil thickness is most commonly used 35um (1oz), there are also thin 18um (O.5oz) or thick 70um (2oz), or even 105um (30z). According to different applications, we have to choose different forms of copper foil. If only to replace wires and connectors, thereby reducing manufacturing time and cost, then well used in reactive circuit board electrolytic copper foil is the best choice. The electrolytic copper foil will also be used to increase the carrying capacity of the current by increasing the weight of the copper, so as to achieve the copper sheet width occasions.

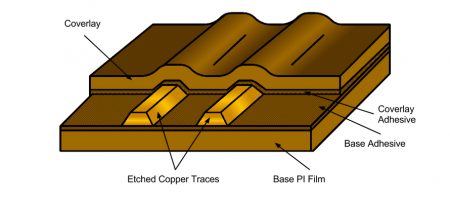

Material of flexible circuit: cover layer

The purpose of the coating is to protect the surface conductors and increase the strength of the substrate. The covering layer is covered on the surface of the flexible printed circuit board to complete a functional layer of insulation protection. There are generally two types of protective materials for the outer graphic. The NovaClad brand, created by Sheldahl, uses a proprietary technology based on vacuum metal-spraying, which applies a very thin layer of pure copper onto the surface of a polyimide film. The material is then electroplated to a specific thickness to form NovaClad’s base material. NovaClad base materials are used in the manufacture of Novaflex flexible circuits without the use of adhesives. After all the circuits have been imaged, a Novaflex insulation coating is applied. Designed to withstand harsh environmental conditions, the Novaflex flexible circuitry provides superior softness, chemical resistance, high-temperature properties, and maximum heat dissipation.

Material of flexible circuit: reinforcement plate

The reinforcement plate is bonded to the local position of the flexible plate to strengthen the flexible film substrate and facilitate the connection, fixation or other functions of the printed circuit board. Reinforced board materials according to the use of different samples, commonly used polyester, polyimide sheet, epoxy glass fiber cloth board, phenolic paper board or steel plate, aluminum plate, etc.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve