- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

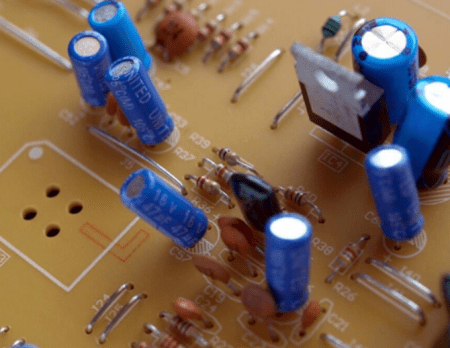

Mastering the key points of SMT is equivalent to grasping the soul of the SMT process technology. No matter how complex and changeable bad welding phenomena are encountered, electronic processing plants can analyze and solve problems in the right direction.

For example, in the SMT patch, if you do not understand that the BGA soldering process of the PCB circuit board has to go through two processes of slump and deformation, it is very difficult to understand the meaning of the BGA soldering peak temperature and soldering time. For another example, it is not easy to understand how complex the mixing process is without knowing that leaded solder paste soldering and lead-free BGA will change the melting point and composition characteristics of the solder joints.

Therefore, when working in an electronic processing factory, it is very important to understand the key points of PCB processing in the SMT chip processing process. It is the underlying knowledge to analyze and solve difficult SMT chip processing problems. Surface mount soldering technology, also known as SMT patch process, is a relatively complex soldering technology, and SMT is constantly evolving, from lead-based process to environmentally friendly lead-free process, from large pad welding to micro-pad welding, PCB processing continuous development and upgrading, but the most basic principles remain the same.

Mastering the process essentials, engineering knowledge, common causes and treatment methods of bad welding phenomena of SMT chip processing can make the SMT chip technology more mature and stable, and establish an effective quality control system. It is of great practical significance to quickly solve the production process problems of SMT chip processing.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve