- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

The heat generated during the operation of the electronic equipment makes the internal temperature of the equipment rise rapidly. If the heat is not released in time, the equipment will continue to heat up, and the device will fail due to overheating, and the reliability of the electronic equipment will decline. Therefore, it is very important to cooling (heat dissipation) the circuit board.

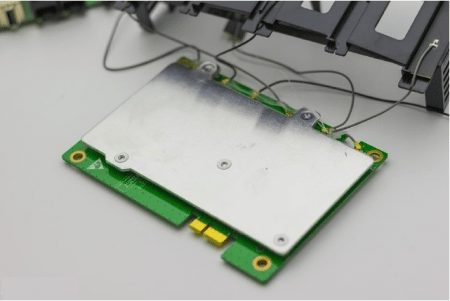

When a few components in THE PCB have high heat (less than 3), heat sink or heat conduction tube can be added to the heating element. When the temperature cannot be lowered, the radiator with fan can be used to enhance the heat dissipation effect. When the number of heating elements is large (more than 3), a large heat sink (panel) can be used. It is a special radiator customized according to the position and height of heating elements on the PCB or a large flat radiator with different height and height of components cut out. The heat dissipation hood shall be fastened on the element surface and contact with each element for heat dissipation. However, the heat dissipation effect is not good due to the poor consistency of components during installation and welding. Soft thermal pads are usually added to the surface of components to improve heat dissipation.

At present, PCB is widely used as copper clad/epoxy or phenolic resin clad glass, and a small amount of paper clad copper. Although these substrates have excellent electrical properties and machining properties, they have poor heat dissipation. As the heat dissipation way of high heating elements, it is almost impossible to rely on the resin of PCB to conduct heat, but to dissipate heat from the surface of components to the surrounding air. However, as electronic products have entered the era of component miniaturization, high-density installation and high-thermal-heating assembly, it is not enough to dissipate heat only on the surface of components with very small surface area. At the same time, due to the extensive use of surface mounted components such as QFP and BGA, the heat generated by components is transferred to THE PCB in large quantities. Therefore, the best way to solve the heat dissipation problem is to improve the heat dissipation ability of the PCB in direct contact with the heating element and conduct or send out through the PCB.

Due to the poor thermal conductivity of the resin in the plate, and copper foil lines and holes are good conductors of heat, so increasing the residual rate of copper foil and increasing thermal conductivity holes are the main means of heat dissipation. To evaluate the heat dissipation capacity of a PCB, it is necessary to calculate the equivalent thermal conductivity (nine eq) of the insulating substrate for the composite material consisting of various materials with different thermal conductivity.

(1) Shorten the lead length of the device as much as possible;

(2) When selecting a high-power device, the thermal conductivity of the lead material should be considered. If possible, the lead horizontal section should be selected to maximize;

(3) Select devices with more pins.

(1) When considering thermal design, attention should be paid to the package description of the device and its thermal conductivity;

(2) Consideration should be given to providing a good heat conduction path between the substrate and the device package;

(3) In the heat conduction path should avoid the air partition, if there is such a situation can be filled with heat conduction materials.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve