- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

For electronic equipment, work will produce a certain amount of heat, so that the internal temperature of the equipment rapidly rise, if the heat is not released in time, the equipment will continue to heat up, the device will fail due to overheating, the reliable performance of electronic equipment will decline. Therefore, it is very important to carry out a good heat dissipation treatment on the circuit board.

PCB design is the downstream process following the principle design, the design quality directly affects the product performance and marketing cycle. As we know, the devices on the PCB board have their own working environment temperature range, if, beyond this range, the working efficiency of the devices will be greatly reduced or fail, resulting in device damage. Therefore, heat dissipation is a key issue to be considered in PCB design.

So, as a PCB design engineer, how should carry out heat dissipation treatment?

PCB heat dissipation and plate selection, the selection of components, components layout and other aspects are related. Among them, the layout of PCB heat dissipation has a decisive role, which is the key link of PCB heat dissipation design. Engineers need to consider the following aspects when making layout:

(1) The components with high heat and high radiation are centrally designed and installed on another PCB board so as to carry out separate centralized ventilation and cooling to avoid mutual interference with the mainboard;

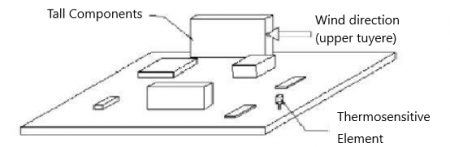

(2) PCB surface heat capacity evenly distributed, do not put the high-power devices concentrated, such as cannot avoid, it is necessary to put the short components in the upstream of the airflow, and ensure that enough cooling airflow through the heat consumption concentration area;

(3) make the heat transfer path as short as possible;

(4) make the heat transfer cross-section as large as possible;

(5) The layout of components shall take into account the influence of thermal radiation on surrounding parts. Heat sensitive components and components (including semiconductor devices) should be kept away from heat or isolated;

(6) pay attention to the direction of forced ventilation and natural ventilation;

(7) The air duct of the additional sub-plate and the device is consistent with the ventilation direction;

(8) as far as possible to make the intake and exhaust have enough distance;

(9) the heating device should be placed above the product as far as possible, and should be on the airflow path when conditions permit;

(10) The components with large heat or current should not be placed in the corners and edges of the PCB board. Radiators should be installed as far as possible and kept away from other devices, and the heat dissipation channel should be unobtainable.

Reminder: adding a radiator to the device is also a good way to dissipate heat.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve