- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

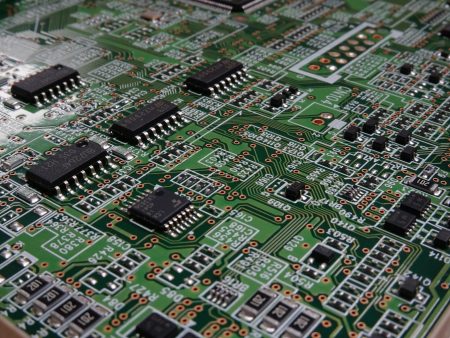

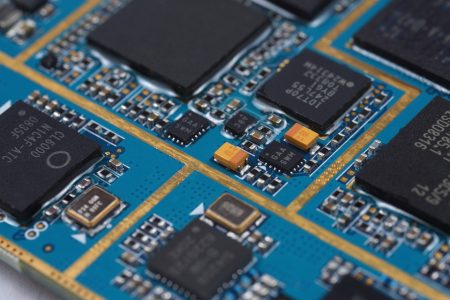

In today’s fast-paced electronics industry, the demand for high-quality printed circuit board assembly (PCBA) has surged. A professional PCBA production team plays a crucial role in meeting this demand, ensuring products are manufactured efficiently, accurately, and to the highest standards. Here, we explore the key elements that contribute to the success of a PCBA production team.

At the heart of a professional PCBA production team lies a deep well of technical expertise. Team members must possess comprehensive knowledge of electronics, circuit design, and manufacturing processes. This includes familiarity with components, assembly techniques, and the latest industry standards. Continuous training and development are essential to keep the team updated on emerging technologies and best practices. This expertise enables the team to troubleshoot issues swiftly and implement innovative solutions that enhance production quality and efficiency.

Having access to advanced manufacturing equipment is critical. A professional PCBA team should utilize state-of-the-art machinery such as surface mount technology (SMT) pick-and-place machines, reflow ovens, and automated optical inspection (AOI) systems. These tools not only improve the speed of production but also ensure precision in assembly. Regular maintenance and upgrades of equipment are vital to minimize downtime and maintain a high production rate.

Quality assurance is paramount in PCBA production. A well-structured quality control system should be in place, covering all stages of the manufacturing process. This includes rigorous inspection of incoming materials, in-process monitoring, and final product testing. Techniques such as statistical process control (SPC) and failure mode and effects analysis (FMEA) can help identify potential issues early, allowing for corrective actions before products reach customers. Implementing ISO certifications can further enhance credibility and customer trust.

The ability to manage projects effectively is crucial for meeting deadlines and managing resources. A skilled project manager can coordinate between various departments—engineering, production, and logistics—to ensure a smooth workflow. This includes planning production schedules, allocating resources efficiently, and tracking progress. Utilizing project management software can help streamline processes and improve communication within the team.

Effective communication is key to any successful team. In a PCBA production environment, clear communication helps prevent misunderstandings and errors. Team members should be encouraged to share insights and challenges openly. Regular meetings and updates can foster a collaborative atmosphere, ensuring everyone is aligned with the team’s goals. Strong communication also extends to interactions with clients, as understanding their needs is vital for delivering customized solutions.

A professional PCBA production team should prioritize customer satisfaction. Understanding the client’s requirements and expectations allows the team to tailor their processes accordingly. Regular feedback loops and client consultations can help identify areas for improvement and innovation. This customer-centric approach not only enhances the product but also builds long-term relationships, leading to repeat business.

A positive team culture fosters collaboration and innovation. Encouraging teamwork among engineers, technicians, and quality control staff can lead to creative problem-solving and increased morale. Regular team-building activities can strengthen relationships and enhance communication, resulting in a more cohesive team. A collaborative environment promotes knowledge sharing, where team members learn from each other’s experiences and expertise.

In the rapidly evolving electronics landscape, a mindset geared toward continuous improvement is essential. Encouraging team members to suggest enhancements to processes and workflows can lead to significant efficiencies. Techniques like Lean manufacturing and Six Sigma can be implemented to reduce waste and improve overall production quality. By fostering a culture of innovation and adaptability, the team can stay ahead of industry trends and demands.

In conclusion, a professional PCBA production team is built on a foundation of technical expertise, advanced equipment, robust quality control systems, effective project management, strong communication skills, a customer-centric approach, collaboration, and a continuous improvement mindset. By focusing on these key elements, organizations can not only enhance their production capabilities but also position themselves as leaders in the competitive electronics market. As the industry continues to evolve, these principles will remain critical to achieving success in PCBA manufacturing.

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve