- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

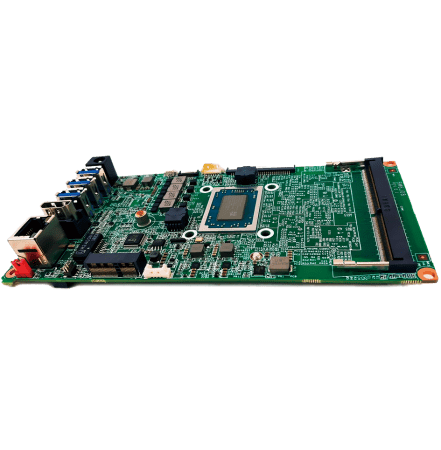

The layout of the PCB test points is as important as the layout of the traces and other components. With the precision design of electronic products getting higher and higher, and the size of products becoming more and more lightweight, when designing PCB circuit boards, in addition to the circuit layout giving engineers a headache, the reasonable setting of PCB test points is also a very brain-burning thing. For circuit board proofing factories, the reasonable layout of PCB test points can not only improve manufacturing efficiency but also reduce the cost of PCB fixtures.

Although the treatment surface can be customized on both sides, it is best to put the points to be tested on one side as the focus of the test;

Implement the priority of measurement points (I..Test points/II..Foot parts/III..Through-hole holes);

The moment between the measured point and the pre-drilled hole is better than 2.54mm;

The measured point should be at least 2.54mm away from the nearby components.

The measured points should be evenly distributed on the PCB circuit board, and it is not recommended to over-arrange the local test;

The diameter of the measuring point shall not be less than 0.7mm;

In addition to the test points, the board also needs to be designed with positioning holes, and there are at most two positioning holes on each PCS circuit board, and the holes cannot be stained with tin;

Before learning how to calculate the number of PCB test points, let’s have a general understanding of what is a PCB test point. For circuit board manufacturers, the factors in estimating the PCB price also include the number of test points, and some manufacturers standard at 30,000 test points per square meter, more than the number of additional on the base price. The charging standard for the number of test points of each company is inconsistent, so how do circuit board manufacturers quickly calculate the number of PCB test points?

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve