- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

As the world moves rapidly into the 5G era, the demand for faster, more reliable, and more efficient communication is increasing exponentially. Whether it’s a 5G base station, a cutting-edge smartphone, or an Internet of Things (IoT) device, the backbone of these technologies lies in high-frequency circuit design and the optimization of Printed Circuit Board Assemblies (PCBA).

These components are integral to ensuring that electronic devices can handle the demands of 5G’s ultra-fast speeds, low latency, and high connectivity. But as frequencies increase, so too do the design challenges. In this blog, we’ll explore the key difficulties involved in high-frequency circuit design and PCBA optimization, and how they can be addressed to support 5G base stations, smartphones, and IoT devices.

At the heart of every 5G device, from base stations to smartphones and IoT devices, lies high-frequency circuitry. With 5G operating in millimeter-wave (24 GHz to 100 GHz) bands, the need for precise and reliable signal transmission is greater than ever. High-frequency circuit design involves several challenges:

As frequencies increase, signal integrity becomes a major concern. High-frequency signals are more susceptible to loss, distortion, and interference. In traditional designs, this might not have been a major issue, but at 5G frequencies, even small imperfections in the PCB can cause significant signal degradation.

Impedance matching is crucial in high-frequency designs. Mismatched impedance between different sections of a circuit can lead to reflections, causing power loss and signal degradation. Achieving consistent impedance across traces, components, and vias is essential for maintaining signal integrity in 5G applications.

At higher frequencies, cross-talk between adjacent traces can lead to unwanted signal interference. The tight packing of components on PCBs, especially in small devices like smartphones, makes it harder to avoid this issue. Careful routing and the use of shielding techniques are required to minimize this risk.

High-frequency circuits often generate more heat, which can degrade performance and reliability. Effective thermal management is crucial to ensure that the components remain within operational temperature limits, especially when they’re packed into compact devices like smartphones and IoT gadgets.

5G base stations are the heart of the 5G network, and their performance is crucial for providing ultra-fast data speeds and connectivity to large numbers of devices. Optimizing PCBA design for 5G base stations presents unique challenges due to the high power requirements and complex signal paths involved.

5G base stations handle much higher power levels than consumer devices like smartphones. The PCBA must be designed to efficiently deliver power to various high-power components (such as RF amplifiers) while preventing overheating or signal degradation. This requires using high-quality materials with low loss factors and incorporating robust power delivery systems to ensure reliability under heavy loads.

To handle high frequencies and reduce signal loss, advanced materials like low-loss laminates (e.g., PTFE or Rogers) are often used in 5G base station PCBs. These materials have excellent high-frequency performance but come at a higher cost compared to standard FR4, which may not be suitable for high-speed, high-frequency designs.

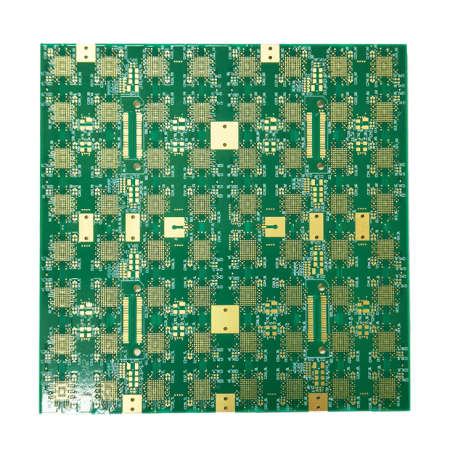

5G base stations require complex multi-layer PCBs with careful routing of high-frequency signal paths. Multi-layer designs allow for better control of impedance and signal integrity by enabling separate signal, power, and ground planes. These planes help reduce electromagnetic interference (EMI) and noise that could degrade performance.

Smartphones are one of the most demanding devices in the 5G ecosystem. As mobile manufacturers pack more features into smaller, thinner devices, optimizing PCBA for high-frequency circuit designs becomes an even greater challenge.

With smartphones, there is a constant push to reduce size while increasing functionality. This means squeezing more high-frequency components into a smaller space, which can exacerbate issues like signal interference, cross-talk, and thermal buildup. To optimize the PCBA for these conditions, careful layout strategies are employed, such as using fine-pitch components and advanced surface-mount technology (SMT) to maximize space.

The integration of 5G antennas into the PCB design is another critical challenge. The antennas must be carefully designed and placed to maximize signal reception and minimize interference. Antenna placement is influenced by factors like PCB material, layout, and the overall mechanical design of the device. Designers must strike a balance between antenna performance and the other functional components in the phone.

With the added power consumption from 5G connectivity, managing heat in smartphones becomes even more challenging. As components generate more heat, they need to be effectively cooled to prevent performance degradation. This might involve using heat sinks, thermal vias, and innovative materials like graphene for improved heat dissipation.

The Internet of Things (IoT) represents another rapidly growing area that benefits from 5G technology. IoT devices are diverse, ranging from smart home products to industrial sensors, and each presents unique challenges for PCBA design and optimization.

Many IoT devices are designed to run on batteries, which makes power efficiency crucial. In the 5G era, IoT devices will need to support high-speed data transmission without compromising battery life. Designers often employ ultra-low-power components, efficient power management ICs, and low-power modes to ensure that these devices can operate for extended periods without recharging.

IoT devices are often deployed in harsh environments, such as outdoor sensors or industrial equipment. The PCBA design must account for factors like moisture, vibration, and temperature extremes. Protective coatings and ruggedized enclosures may be needed to ensure the longevity and reliability of the device in these conditions.

For many IoT devices, size and cost are major factors. Components must be compact, yet still able to handle the high-speed requirements of 5G connectivity. This makes choosing the right materials and optimizing the PCB layout especially important to ensure that performance isn’t compromised while maintaining a cost-effective solution.

Across all types of devices—whether base stations, smartphones, or IoT gadgets—several key strategies can be employed to optimize PCBA design for high-frequency circuits:

High-frequency PCBs require materials with low dielectric loss, such as PTFE, Rogers, or ceramic-based substrates. These materials help maintain signal integrity at higher frequencies and reduce loss and distortion.

In high-frequency designs, controlling impedance throughout the PCB layout is essential. Designers use impedance-controlled traces and vias to prevent signal reflections and ensure consistent performance across the board.

Shielding and grounding techniques are used to minimize EMI and crosstalk between components. Proper grounding is crucial to ensure that high-frequency signals don’t interfere with each other, especially in densely packed PCBs.

Before finalizing a design, engineers often use simulation tools to model the behavior of high-frequency circuits and predict potential issues related to signal integrity, thermal performance, and impedance matching. Prototyping and testing are essential to ensure that the final product meets performance and reliability standards.

As 5G technology continues to evolve, optimizing high-frequency circuit design and PCBA will be crucial for ensuring the performance and reliability of devices ranging from base stations to smartphones and IoT devices. By addressing the unique challenges of high-frequency design—such as signal integrity, thermal management, and impedance control—engineers can create more efficient, compact, and durable solutions that can fully harness the power of 5G. Whether you’re designing a 5G base station or a next-generation IoT device, staying on top of these challenges will be key to success in the rapidly advancing 5G landscape.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve