- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

The evolution of electronic devices has propelled advancements in Printed Circuit Board Assembly (PCBA) services. As the demand for compact, efficient, and high-performance electronics increases, the integration of High-Density Interconnect (HDI) PCBs and the strategic use of blind via and buried via designs have become essential. These technologies streamline PCBA processes, enhance product quality, and address the growing complexities of modern electronic systems. In this blog, we explore how HDI PCBs and advanced via designs optimize PCBA service processes.

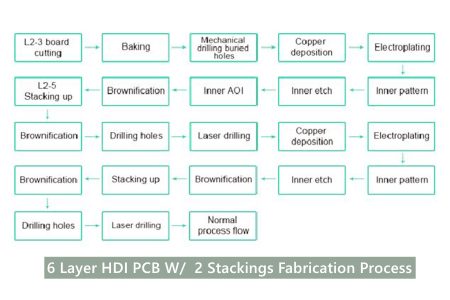

High-Density Interconnect (HDI) PCBs are characterized by their fine lines, small vias, and high component density. They support intricate designs and advanced functionalities, making them indispensable for industries like consumer electronics, automotive, medical devices, and aerospace. The key features of HDI PCBs include:

These characteristics directly impact PCBA processes by offering enhanced design flexibility and facilitating the integration of complex components.

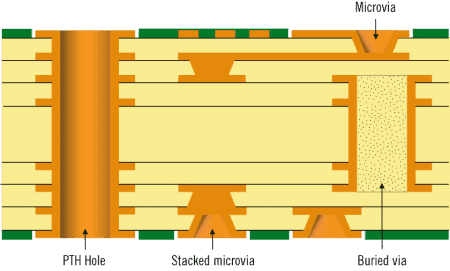

Blind vias and buried vias are essential design elements in HDI PCBs, contributing significantly to their functionality:

These via types enable efficient multilayer designs, reducing the overall size of PCBs while maintaining functionality. They also play a critical role in minimizing signal interference and improving electrical performance.

The compact nature of HDI PCBs with blind and buried vias allows engineers to achieve intricate designs with reduced board size. This efficiency minimizes the need for extensive routing and enhances the assembly process, resulting in faster production cycles.

The additional surface space made available by blind vias facilitates the placement of more components or larger chips. Automated assembly equipment can place these components with higher precision, reducing errors and rework.

By reducing the distance between layers and minimizing via lengths, HDI designs with blind and buried vias enhance signal integrity. This capability is crucial for high-frequency applications where signal degradation can compromise functionality.

Advanced via technologies simplify the layer-to-layer connection process, reducing the overall complexity of PCB manufacturing. This simplification translates into more efficient PCBA workflows and cost savings.

Blind and buried vias can serve as thermal conduits, dissipating heat more effectively from critical areas. This feature ensures stable operation, particularly in high-power devices, and minimizes the risk of component failure.

Several industries benefit from the integration of HDI PCBs and blind/buried via designs in PCBA processes:

The integration of HDI PCBs and blind/buried via designs revolutionizes PCBA service processes by addressing the complexities of modern electronic systems. From enhancing design flexibility to improving signal performance and thermal management, these technologies offer comprehensive solutions for high-performance applications. As industries continue to demand more from electronic devices, adopting HDI technology and advanced via designs will be pivotal in meeting these challenges and driving innovation forward.

XPCB Limited: Your One-Stop Solution for PCB Manufacturing and Assembly

XPCB Limited is your one-stop solution for all your PCB manufacturing and assembly needs. From design and prototyping to full-scale production, we offer comprehensive services under one roof. With a focus on quality, efficiency, and customer satisfaction, we make it easy for you to complete your projects with confidence. Simplify your PCB process today with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve