- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In today’s fast-paced electronics market, PCB assembly has become a critical factor in determining the success of a product. Whether you’re creating consumer electronics, medical devices, or industrial equipment, the efficiency, reliability, and speed of your PCB assembly process can significantly impact time-to-market and production costs. One solution that has gained widespread popularity among OEMs (Original Equipment Manufacturers) and EMS (Electronics Manufacturing Services) providers is turnkey PCB assembly.

In this blog, we’ll explore how turnkey PCB assembly solutions can help you streamline your production process, reduce costs, and ultimately improve the quality and reliability of your end products. We will also discuss the benefits, process flow, and best practices for optimizing PCB assembly with turnkey services.

Turnkey PCB assembly refers to a comprehensive service where a single provider manages the entire process of PCB production and assembly—from the initial design and prototyping stage to component sourcing, assembly, testing, and final delivery. Essentially, a turnkey solution handles every aspect of the PCB assembly process, allowing the customer to focus on other areas of product development.

Design support: Helping with circuit board layout, simulation, and optimization.

Component sourcing: Procurement of all required parts, including passive and active components.

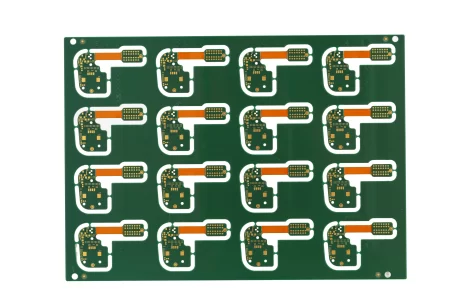

PCB fabrication: Manufacturing the PCB based on the design specifications.

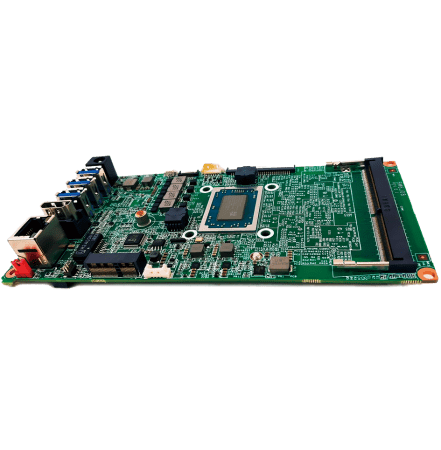

Assembly: Placing and soldering the components onto the PCB using automated machines like SMT (Surface Mount Technology) or THT (Through-Hole Technology).

Testing and inspection: Running quality checks like In-Circuit Testing (ICT), Automated Optical Inspection (AOI), and functional testing to ensure proper performance.

Final assembly and packaging: Putting the final product together and preparing it for shipment.

By using a turnkey provider, you eliminate the need for managing multiple vendors, streamlining your operations and ensuring smoother coordination throughout the entire PCB assembly process.

One of the primary benefits of a turnkey PCB assembly service is cost efficiency. Managing multiple vendors for different stages of the PCB assembly process—such as sourcing components, fabricating the PCB, and assembling the board—can incur high overhead costs. With a turnkey solution, you consolidate these services with a single provider, which often results in lower overall costs due to economies of scale, reduced shipping costs, and the ability to negotiate better pricing for components.

Additionally, turnkey services help minimize the risks associated with component shortages or delays. Since the assembly provider sources and manages components, they are better able to foresee supply chain issues and prevent production delays, helping to keep costs under control.

Turnkey PCB assembly also plays a crucial role in accelerating time-to-market. Traditional PCB assembly processes often involve multiple phases with different vendors, which can lead to delays in component sourcing, fabrication, or assembly. With a turnkey solution, all steps are managed by one company, ensuring faster turnaround times and reduced risk of delays.

Moreover, many turnkey providers offer quick-turn prototyping services, allowing customers to get a working prototype of their PCB in as little as 24 to 48 hours. This rapid prototyping enables designers to test and refine their designs quickly, cutting down on development time and enabling faster product launches.

A key advantage of turnkey PCB assembly is the ability to maintain strict quality control throughout the entire process. Since the turnkey provider handles all stages of production, there is greater control over the consistency and quality of the parts, assembly, and testing. Many turnkey manufacturers also implement robust quality checks, including:

Automated Optical Inspection (AOI): Checks for visible defects such as misaligned components, poor solder joints, or incorrect component placement.

In-Circuit Testing (ICT): Ensures that the assembled board functions properly by testing for electrical continuity and component functionality.

X-ray inspection: Especially useful for checking complex components like BGAs (Ball Grid Arrays) that might not be visible using traditional inspection methods.

By consolidating quality assurance under one provider, you can ensure that your products meet high standards, reducing the chances of defective units reaching the market.

Managing multiple suppliers for different phases of PCB assembly can create a communication bottleneck, leading to misunderstandings, errors, or delays. A turnkey provider eliminates the need for you to juggle different suppliers by offering a single point of contact throughout the entire process.

This streamlines communication, reduces the risk of errors, and helps keep the project on track. With a turnkey service, you’ll have dedicated project managers who oversee every detail of the process, providing updates and addressing any potential issues before they become problems.

Turnkey PCB assembly services are highly scalable, making them ideal for both low-volume and high-volume production. Whether you are developing a prototype for a new product or ramping up for mass production, turnkey providers have the capabilities and expertise to support your needs at any stage of production. As your product moves from prototyping to full-scale manufacturing, a turnkey solution ensures that your assembly process remains efficient, flexible, and cost-effective.

Design and Prototyping: The design team works with the client to optimize the PCB layout for performance and manufacturability. The prototype is created and tested for functionality.

Component Sourcing: The turnkey provider sources all the components needed for the assembly, including resistors, capacitors, ICs, and connectors. This is a critical step, as it ensures that all components meet the specifications and are readily available.

PCB Fabrication: The PCB is fabricated according to the specifications, and the board is prepared for assembly. This stage may involve etching, drilling, and the creation of copper layers for signal and power routing.

Assembly: The PCB is populated with components using SMT (Surface Mount Technology) or THT (Through-Hole Technology), depending on the design requirements. Automated placement machines are used to ensure high precision.

Testing and Quality Control: Once the assembly is complete, thorough testing is carried out to ensure the PCB functions as intended. This includes in-circuit testing, visual inspection, and functional testing.

Packaging and Delivery: After passing all tests, the completed product is carefully packaged and shipped to the customer.

Best Practices for Optimizing Your Turnkey PCB Assembly Process

To get the most out of your turnkey PCB assembly service, consider these best practices:

Clear Design Specifications: Provide your turnkey provider with detailed and accurate design files (e.g., Gerber files), component lists (e.g., Bill of Materials (BOM)), and any specific requirements for testing and assembly.

Early Prototyping: Use early-stage prototyping to test your designs before committing to full-scale production. This helps identify potential issues early and reduces the risk of costly revisions.

Component Selection: Work closely with your turnkey provider to select the right components for your design. They can help identify component obsolescence, availability issues, and recommend alternative parts if needed.

Communication: Maintain open and regular communication with your turnkey provider to ensure that any potential issues are addressed promptly and the project remains on track.

Optimizing your PCB assembly process with turnkey solutions offers numerous advantages, including cost reduction, faster time-to-market, improved quality, and simplified project management. By choosing a turnkey provider to handle everything from design and prototyping to testing and delivery, you can streamline the production process, reduce risks, and ensure your products meet the highest standards of quality and performance. Whether you’re developing a new product or scaling up for mass production, a turnkey PCB assembly solution can help you bring your ideas to life quickly and efficiently.

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve