- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

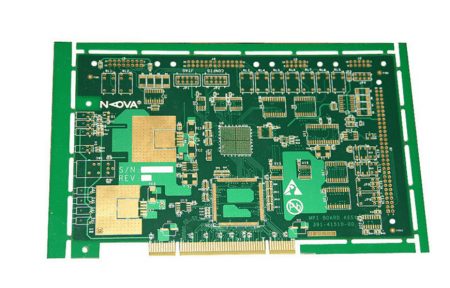

The step of “PCB packaging” is highly valued in PCB factories. The main reason is that it does not produce added value on the one hand, and on the other hand, the manufacturing industry has not paid attention to products for a long time. The unmeasured benefits that can be brought by the packaging of the PCB. Therefore, if a PCB company can make small improvements from the “packaging”, there may be great results. Another example is that Flexible PCB is usually a small piece and the quantity in many cases, if a good packaging method is adopted, the packaging container is specially opened for the shape of a certain product, so that it is convenient to use and has a protective effect.

First, the discussion of early packaging.

For the early packaging, see the outdated shipping packaging methods in the table, showing its advantages and disadvantages. There are still some small factories that use these methods for packaging.

Domestic PCB production capacity is expanding rapidly, and most of it is for export. Therefore, the competition is very fierce, not only the competition among domestic factories, but also the competition with the top two PCB factories in the United States and Japan, in addition to the technical level and quality of the products being affirmed by customers, the quality of packaging must be approved by customers. Almost large-scale electronics factories now require PCB manufacturers to ship packages. The following items must be paid attention to, and some even directly give specifications for shipping packaging.

1. Must be vacuum packed.

2. The number of boards per stack is limited depending on the small size.

3. The specifications for the tightness of each stack of PE film and the width of the margin.

4. Specification requirements for PE film and air bubble sheet.

5. Carton weight specifications and others.

6. Any special regulations for buffering before placing the board inside the carton.

7. The tolerance rate specification after sealing.

8. The weight of each box is limited.

At present, the domestic vacuum skin packaging is similar, the main difference is only the effective working area and the degree of automation.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve