- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

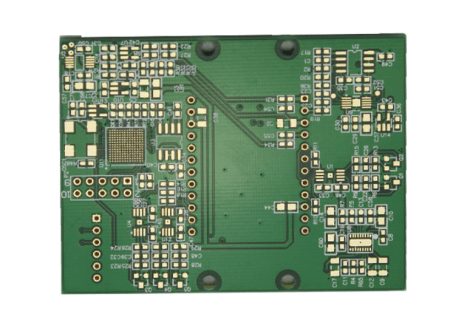

Copper pour is to use the unused space on the PCB as a reference surface and then fill it with solid copper. These copper areas are also called copper filling. The significance of copper coating is to reduce the bottom line impedance, improve the anti-interference ability, reduce the voltage drop, improve the power efficiency, and connect to the ground wire to reduce the loop area. If the PCB has a lot of ground, such as SGND, AGND, GND, how to pour copper? According to the position of the PCB board, the main bottom line is used as the reference to pour copper independently, and the digital ground and analog ground are separated to pour copper. At the same time, before the copper pour, first thicken the corresponding power connection: V5.0V, V3.6V, V3.3V (SD card power supply), etc., in this way, a plurality of polygonal structures with different shapes are formed.

There are several problems to be dealt with in copper coating: one is the single-point connection to different grounds, and the other is the copper coating near the crystal oscillator. The crystal oscillator in the circuit is a high-frequency emission source. The method is to surround the crystal oscillator with copper and then ground the crystal oscillator separately. The third is the island (dead zone) problem, you can define a ground via to add it.

In addition, it is impossible to say whether large-area copper pour is better or network copper pour is better. For large area copper plating, if wave soldering is used, the board may be uplifted or even blistered. From this point of view, the grid has better heat dissipation. Generally, high-frequency circuits require high multi-purpose grids, and low-frequency circuits have high-current circuits and other commonly used complete copper coatings.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve