- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

PCB manufacturing is a very complex process. So learning the PCB glossary is the basic literacy of PCB industry personnel. XPCB Limited summarizes some of the PCB glossary sharing.

Accelerator: A chemical that is used to speed up a reaction or cure, as cobalt naphthenate is used to accelerate the reaction of certain polyester resins. It is often used along with a catalyst, hardener, or curing agent. The term “accelerator” is often used interchangeably with the term “promoter”.

Catalyst: A chemical that causes or speeds up the cure of a resin but does not become a chemical part of the final product.

Accuracy: The ability to place the hole at the targeted location.

Additive process: A process for obtaining conductive patterns by the selective deposition of conductive material on an unclad base material.

Adhesive: Broadly, any substance used in promoting and maintaining a bond between two material

Aging: The change in properties of a material with time under specific conditions..

Annular ring: The circular strip of conductive material that completely surrounds a hole.

Arc resistance: The time required for an arc to establish a conductive path in a material

Artwork master: An accurately scaled configuration used to produce the production master.

Image 1: Annular ring of PCB glossary

Backup material: A material placed on the bottom of a laminate stack in which the drill terminates its drilling stroke.

Base material: The insulating material upon which the printed wiring pattern may be formed.

Base material thickness: The thickness of the base material excluding metal foil cladding or material deposited on the surface.

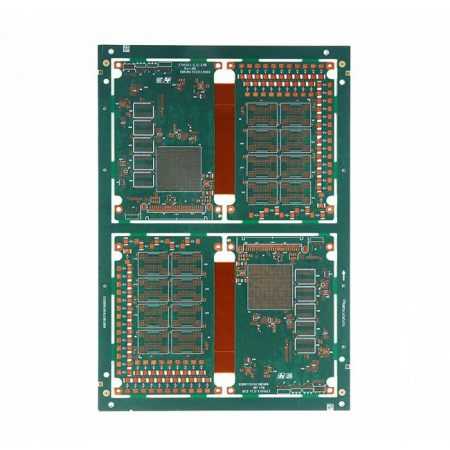

Bind via: Conductive surface hole that connects an outerlayer with an innerlayer of a multilayer PCB without penetrating the entire board.

Buried via: Conductive surface hole that connects one innerlayer to another innerlayer of a multilayer PCB without having a direct connection to either the top or bottom surface layer.

Blistering: Localized swelling and separation between any of the layers of the base laminate or between the laminate and the metal cladding.

Burr: A ridge left on the outside copper surfaces after drilling

Bonding layer: An adhesive layer used in bonding other discrete layers during lamination.

Bond strength: The force per unit area required to separate two adjacent layers by a force perpendicular to the board surface; usually refers to the interface between copper and base material.

Bow: A lamination defect in which deviation from planarity results in a smooth arc.

B-stage: An intermediate stage in the curing of a thermosetting resin. In it a resin can be heated and caused to flow, thereby allowing final curing in the desired shape.

B-stage lot: The product from a single mix of B-stage ingredients.

B-stage resin: A resin in an intermediate stage of a thermosetting reaction. The material softens when heated and swells when in contact with certain liquids, but it may not entirely fuse or dissolve.

Image 2: Blind Buried Hole Multilayer PCB by XPCB

Capacitance: The property of a system of conductors and dielectrics which permits the storage of electricity when potential difference exists between the conductors.

Capactive coupling: The electrical interaction between two conductors caused by the capacitance between the conductors.

Carbide: Tungsten carbide, formula WC. The hard, refractory material forming the drill bits used in PCB drillings.

Ceramic leaded chip carrier (CLCC) : A chip carrier made from ceramic (usually a 90-96% alumina or beryllia base) and with compliant leads for terminations.

Chip carrier (CC): An integrated circuit package, usually square, with a chip cavity in the center; its connections are usually on all four sides.(See leaded chip carrier and leadless chip carrier.)

Chip load (CL) : The movement of the drill downward per revolution; usually given in mils (thousandths of an inch) per revolution

Chlorinated hydrocarbon: An organic compound having chlorine atoms in its chemical structure.

Circuit: The interconnection of a number of electrical devices in one or more closed paths to perform a desired electrical or electronic function.

Clad: A condition of the base material, to which a relatively thin layer or sheet of matel foil (cladding) has been bonded on one or both of its sides. The result is called a metal-clad base material.

CNC: Computer numerically controlled. Refers to a machine with a computer which stores the numerical information about location , drill size, and machine parameters, regulating the machine to carry out that information.

Coat: To cover with a finishing, protecting, or enclosing layer of any compound.

Image 2: CNC Drilling Machine

Make Your PCB Dreams a Reality with XPCB Limited

XPCB Limited is your go-to partner for turning your PCB dreams into reality. Our streamlined PCB manufacturing process, combined with quick-turnaround prototyping and turnkey PCBA services, ensures that your projects come to life with ease. Trust in our expertise and dedication to quality as we help you achieve your PCB goals. Join us and experience the difference with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve