- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Many industrial PCB-based applications that make use of high power are commonly associated with mobile base station technology; nevertheless, there are other applications. There are also a number of points to consider when collaborating with high-power RF applications. This column will focus on PCB-based power amplifiers utilized in base station applications, yet the basic ideas discussed here will apply to other high-power applications.

A lot of high-power RF applications will certainly have issues with thermal management, as well as there are a couple of essential connections to consider. One relationship is the loss-heat partnership. A circuit with greater loss will trigger greater heat to be created when high RF power is used. An additional problem is a frequency warm, which creates extra warmth to be created at higher frequencies. Additionally, any kind of dielectric product that is subjected to a boost in warmth will have a modification in Dk (dielectric continuous), and that is the thermal coefficient of the dielectric constant (TCDk). There will also be an adjustment in insertion loss with an adjustment in temperature.

These changes in Dk as a result of TCDk can impact the RF circuit efficiency and could be troublesome for the application. There are multiple materials and PCB residential or commercial properties that must be resolved for the lost heat partnership. Occasionally, when a developer selects a low-loss product for a PCB application, they will only think about the dissipation variable (Df, or loss tangent). The Df is connected to the dielectric losses of the material; however, a circuit will certainly have other losses. The overall loss of a circuit, as it relates to RF efficiency, is insertion loss. Insertion loss is comprised of 4 other losses as well as is a summation of dielectric loss, conductor loss, radiation loss, as well as leak loss.

A circuit utilizing an extremely reduced loss material with a Df of 0.002 as well as really smooth copper will have relatively reduced insertion loss. The same circuit utilizing the very same low-loss product, but utilizing a top-level electrodeposited (ED) copper as opposed to smooth copper will certainly bring about an increase in insertion loss.

Copper surface area roughness will certainly influence the conductor loss of a circuit. To be clear, the surface area roughness that is an issue for losses is the copper surface area roughness at the copper-substrate interface as the laminate is made. Furthermore, if the circuit substrate is thin, the copper planes will be closer together, and also the copper surface roughness will have a larger influence on insertion loss contrasted to a circuit using a thicker laminate.

For high-power RF applications where thermal management is commonly a problem, selecting a laminate with reduced Df and also smooth copper can be useful. Additionally, selecting a laminate with high thermal conductivity is normally a smart point to do too. The high thermal conductivity will certainly help in relocating the heat better out of the circuit as well as into the warm sink.

The frequency-heat relationship generally triggers warmer to be generated when there is a rise in frequency, with the assumption of the very same RF power being applied at both frequencies. As an instance taken from some thermal administration experiments done at Rogers, we discovered that a microstrip transmission line with a used RF power of 80 watts at 3.6 GHz had a warmth surge of ≈ 50 ° C. When that same circuit was examined with 80 watts applied at 6.1 GHz, the heat rise was ≈ 80 °C. There are several factors for having a rise in temperature levels with an increase in frequency.

One factor is the Df of material will certainly boost with a raised regularity, which will trigger more dielectric losses as well as will inevitably cause a boost in insertion loss and also warmth. One more issue is the fact that conductor losses normally increase with a rise in frequency. Some of the conductor loss increase is due to a thinning of skin depth as frequency boosts.

Additionally, with boosted frequency, the areas will condense, and also there will be much more power density in a given location of the circuit, which will also increase the healing impacts. Finally, TCDk, which has actually been stated a number of times in this column formerly since it is a material building that is frequently neglected, is primarily how much the Dk will certainly alter with an adjustment in temperature level.

In the case of power amplifier circuits, they frequently have 1/4 wavelength matching networks, and these networks are sensitive to DK changes. When the DK modifications significantly, the 1/4 wavelength matching will certainly move, and also the power amplifier can differ inefficiency, which is really unfavorable.

In summary, when choosing high-frequency products for high-power RF applications, the product needs to have reduced Df, fairly smooth copper, high thermal conductivity, as well as a reduced TCDk. There are many tradeoffs when considering these material residential or commercial properties, together with the final end-use application requirements. Consequently, it is constantly wise for the developer to contact their material provider when picking materials for high-power RF applications.

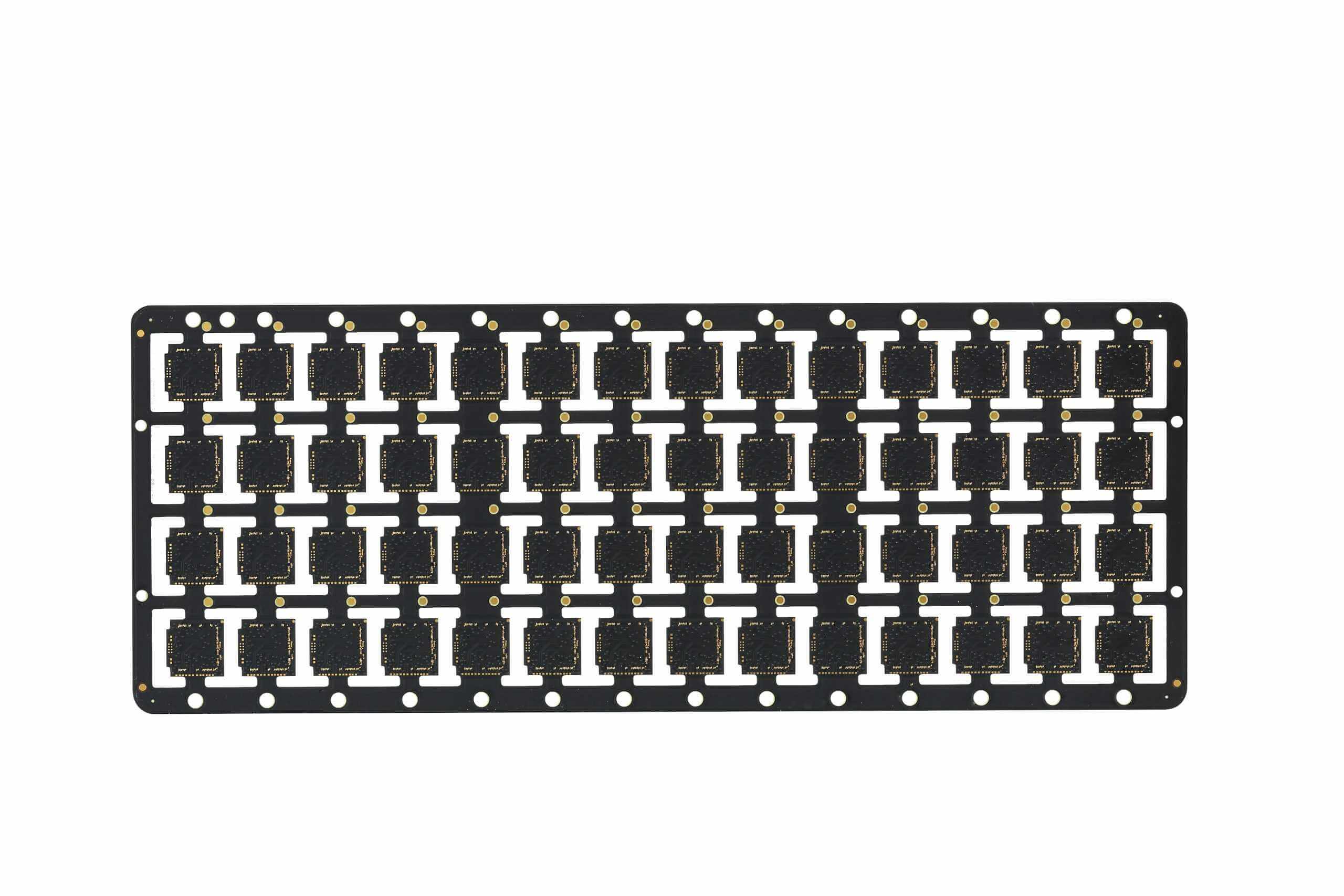

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve