- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

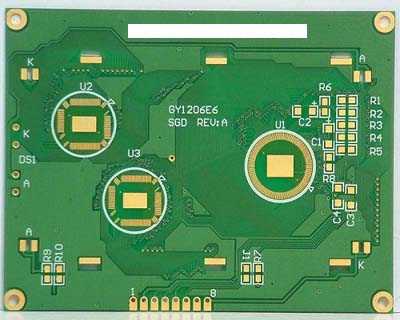

PCB plating process: pickled → full board electroplated copper → pattern transfer→ acid degreasing→ secondary countercurrent rinsing→micro etching→ secondary countercurrent rinsing→ pickling → tin plating→ secondary countercurrent rinsing→ countercurrent rinsing→ pickling → pattern copper plating→ secondary countercurrent rinsing→ nickel plating→ secondary washing→ citric acid → gold plating → recycling→ 2-3 pure water washing→ drying,

Remove the oxide on the plate surface, activate the plate surface, and generally control the concentration at about 5%-10%, mainly to prevent the instability of the sulfuric acid content of the tank solution caused by the introduction of water; The acid leaching time should not be too long to prevent the oxidation of the PCB board; After a period of use, when the acid is turbid or the copper content is too high, it should be replaced in time to prevent contamination of the surface of the electroplated copper cylinder and plates.

Also known as “primary copper”, protects the freshly deposited thin electroless copper, and to prevent the electroless copper from being eroded by acid after oxidation, it is added to a certain extent through electroplating. The main components of the tank solution are “copper sulfate” and “sulfuric acid”, and the formula of high acid and low copper is adopted to ensure the uniformity of the thickness distribution of the PCB board surface during electroplating and the deep plating ability of deep holes and small holes; The sulfuric acid content is controlled at about 180-240 g/L;

The copper sulfate content is generally about 75 g/L, and a trace amount of chloride ions is added to the tank solution as an auxiliary gloss agent and copper light agent to play a glossy effect; The additional amount of copper light agent or the amount of opening the cylinder is generally 3-5ml/L, and the addition of copper light agent is generally supplemented according to the method of 1,000-ampere-hours or according to the actual production effect of the board;

The current calculation of PCB full board plating is generally 2 amps/square decimeter multiplied by the plateable area on the board, for full board plating, that is, the board length dm× board width dm×2×2A/DM2; The temperature of the copper cylinder is maintained at room temperature, and the general temperature does not exceed 32 degrees, and it is mostly controlled at 22 degrees, so in summer, because the temperature is too high, the copper cylinder is recommended to install a cooling temperature control system.

Remove oxides on the copper surface of the line, ink residue residue, and ensure the adhesion between primary copper and graphic electroplating copper or nickel.

Clean the copper surface of the roughened circuit to ensure the adhesion between the graphic electroplating copper and the primary copper. The micro-etching agent uses sodium persulfate, the roughening rate is stable and uniform, the water washing is good, the concentration of sodium persulfate is generally controlled at about 60 g/L, the time is controlled at about 20 seconds, and the drug is added by 3-4 kg per 100 square meters; The copper content is controlled below 20 g/L; Other maintenance cylinders are micro-etched with copper sinking.

Remove oxides on the circuit board surface and activate the board surface, the general concentration is about 5%-10%, so as to prevent the unstable sulfuric acid content of the tank solution caused by water introduction; The acid leaching time should not be too long, in order to prevent oxidation of the plate surface; After a period of use, the acid should be replaced in time when it appears cloudy or the copper content is too high.

It is also called “secondary copper”, in order to meet the rated current load of each line, each line and hole copper need to reach a certain thickness, the purpose of line copper plating is to thicken the hole copper and line copper to a certain thickness in time; All other items are the same as full plate plating.

The metal resist layer is the main component of pure tin for graphic electroplating to protect the circuit etching; The bath solution is mainly composed of stannous sulfate, sulfuric acid and additives; The content of stannous sulfate is controlled at about 35 g/L, and the sulfuric acid is controlled at about 10%; The addition of tinning additives is generally supplemented according to the method of 1,000 ampere hours or according to the actual production effect of the board;

The current calculation of electrotin plating is generally 1. 5 amps/square decimeter multiplied by the electroplateable area on the plate; The temperature of the tin cylinder is maintained at room temperature, the temperature does not exceed 30 degrees, and it is mostly controlled at 22 degrees, so in summer, because the temperature is too high, it is recommended to install a cooling temperature control system for the tin cylinder;

The nickel plating layer is mainly used as a barrier layer between the copper layer and the gold layer to prevent the gold and copper from diffusing each other, affecting the solderability and service life of the board; At the same time, the nickel layer is primed, which also greatly increases the mechanical strength of the gold layer; Copper plating related process parameters of the whole plate: the addition of nickel plating additives is generally supplemented according to the method of 1,000 ampere hours or according to the actual production effect of the plate, and the addition amount is about 200ml/KAH;

The current calculation of graphic nickel plating is generally calculated by multiplying 2 amps/square decimeter by the electroplateable area on the plate; The temperature of the nickel cylinder is maintained at 40-55 degrees, and the temperature is about 50 degrees, so the nickel cylinder should be equipped with a heating and temperature control system;

Divided into electroplating hard gold (gold alloy) and water gold (pure gold) process, the composition of hard gold plating and soft gold tank is basically the same, but there are some trace metal nickel or cobalt or iron and other elements in the hard gold tank; As a precious metal, gold has good weldability, oxidation resistance, corrosion resistance, small contact resistance, good alloy wear resistance and other excellent characteristics;

The gold plating of the circuit board is mainly gold citrate bath, and the gold content of water gold is controlled at about 1 g/L, and the pH value is 4. 5 or so, the temperature is 35 degrees, the specific gravity is about 14 Baumé, and the current density is about 1 ASD; The main added drugs include acid adjustment salts and alkaline adjustment salts to adjust PH value, conductive salts to adjust specific gravity, gold-plating supplementary additives and gold salts, etc.;

In order to protect the gold cylinder, a citric acid immersion tank should be added before the gold cylinder, which can effectively reduce the pollution of the gold cylinder and keep the gold cylinder stable; After the gold plate is electroplating, a pure water wash should be used as the recovery water washing, and at the same time, it is used to supplement the liquid level of the evaporation change of the gold tank.

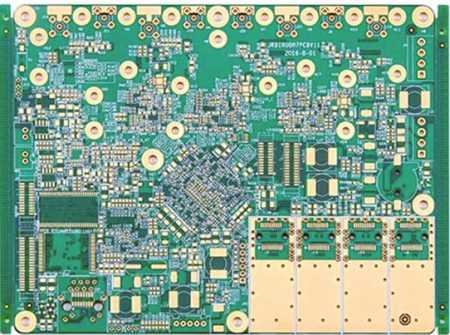

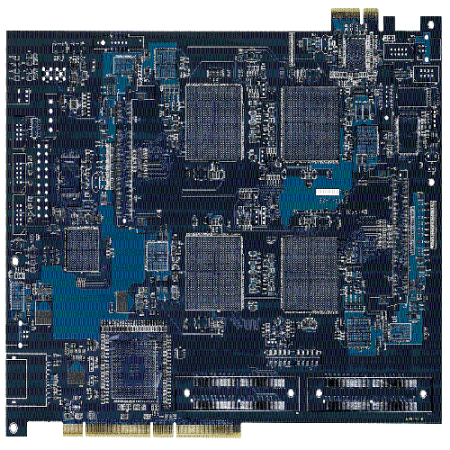

Simplify Your PCB Journey with XPCB Limited

XPCB Limited simplifies the PCB process for you. With our quick-turnaround prototyping and turnkey PCBA services, we ensure that your projects move forward smoothly and efficiently. Trust our commitment to quality and timeliness as we help you bring your designs to life. Choose XPCB Limited for a hassle-free PCB experience.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve