- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

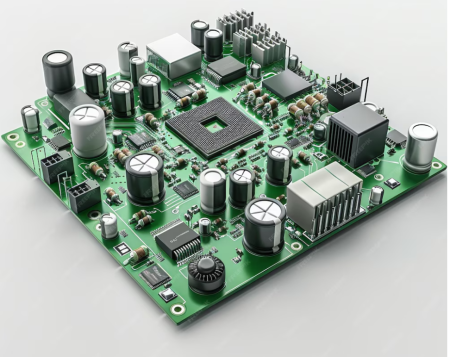

In recent years, the demand for precision PCB (Printed Circuit Board) assembly has skyrocketed, particularly in the context of the Chinese market. This surge can be attributed to several factors, including technological advancements, the growing electronics industry, and the increasing complexity of electronic devices. As China continues to solidify its position as a global manufacturing powerhouse, understanding the nuances of precision PCB assembly becomes essential for stakeholders in this field.

China has long been recognized as a leader in electronics manufacturing, providing a significant percentage of the world’s electronics. The country’s robust supply chain, skilled workforce, and advanced manufacturing technologies have made it an ideal location for PCB assembly. Precision PCB assembly involves not just the assembly of circuit boards, but also the meticulous placement of components, soldering, and quality control measures that ensure the reliability and functionality of the final product.

With the growth of the Internet of Things (IoT), artificial intelligence (AI), and smart devices, the complexity of PCBs has increased dramatically. Modern electronic products require highly intricate designs and precise assembly techniques. This trend has placed a premium on precision PCB assembly, as manufacturers strive to meet the demands of a rapidly evolving market.

Technological advancements in assembly techniques have played a pivotal role in enhancing the precision of PCB manufacturing. Automated machines, such as pick-and-place robots, are now capable of placing thousands of components per hour with remarkable accuracy. These machines are equipped with advanced vision systems that allow for real-time quality checks, minimizing the risk of errors during the assembly process.

Additionally, innovations in soldering techniques, such as selective soldering and reflow soldering, have improved the reliability of connections on PCBs. These methods ensure that solder is applied precisely where needed, reducing the chances of shorts and enhancing the overall durability of the circuit boards.

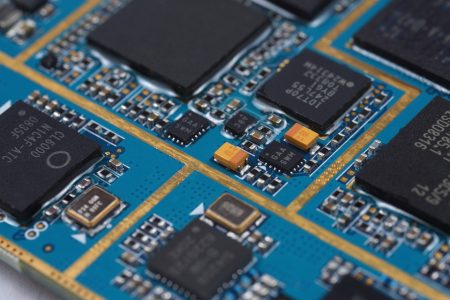

The current Chinese market for precision PCB assembly is characterized by several key trends. First, there is a growing demand for miniaturization. As consumer electronics become smaller and more powerful, manufacturers are tasked with designing PCBs that can accommodate this trend. This often requires advanced design techniques and high-precision assembly methods to ensure that all components fit within the limited space without compromising performance.

Second, sustainability is becoming an important consideration. As environmental regulations tighten, manufacturers are increasingly looking for eco-friendly materials and processes in their PCB assembly practices. This shift not only helps reduce the environmental impact but also aligns with the growing consumer preference for sustainable products.

However, the market is not without its challenges. The ongoing trade tensions and supply chain disruptions have forced many manufacturers to rethink their sourcing strategies. Companies are now more focused on developing resilient supply chains that can withstand external shocks, which sometimes means diversifying their supplier base or investing in local sourcing options.

Quality control remains a critical aspect of precision PCB assembly. In a market that demands high reliability, manufacturers must implement rigorous testing and inspection processes. This includes automated optical inspection (AOI), X-ray inspection, and functional testing to ensure that each PCB meets the required specifications.

Furthermore, adhering to international standards such as IPC-A-610 (Acceptability of Electronic Assemblies) ensures that manufacturers maintain a high level of quality and consistency. Compliance with these standards not only helps in producing reliable products but also enhances a company’s credibility in the global market.

As the Chinese market for precision PCB assembly continues to evolve, stakeholders must stay informed about the latest trends, technologies, and challenges. With the increasing complexity of electronic devices, the importance of precision in PCB assembly cannot be overstated. By leveraging advanced technologies, prioritizing quality control, and adapting to market demands, manufacturers can position themselves for success in this competitive landscape.

In conclusion, the future of precision PCB assembly in China is bright, but it requires a commitment to innovation, quality, and sustainability. Companies that embrace these principles will not only thrive in the current market but also shape the future of electronics manufacturing.

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve