- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

This is a 10 layer rigid flex PCB built by XPCB Ltd, applied in medical electronics. It is with 2R+2F+2F+2F+2R stackup, 2.0mm final thickness. XPCB is a dedicated manufacturer of rigid flex printed circuit board based in Shenzhen, China. We offer QTA, free DRC & DFM checking, turnkey assembly service.

Quick-turn rigid-flex PCB services offer rapid prototype development and production, enabling engineers to expedite design iterations and meet tight deadlines. Our advanced rigid-flex PCB technology offers swift and reliable rigid-flex PCB prototyping. Whether you need custom design or fast-turn Rigid-Flex PCB services, our commitment to quality and innovation ensures that you receive top-notch solutions for your products.These specialized services leverage advanced manufacturing techniques for industries like aerospace, medical devices, automotive, and consumer electronics. By prioritizing speed without compromising quality, quick-turn rigid-flex PCB solutions streamline innovation, optimize product performance, and ensure seamless integration with manufacturing processes.

With XPCB’s quick-turn rigid-flex PCB prototyping service, you’ll benefit :

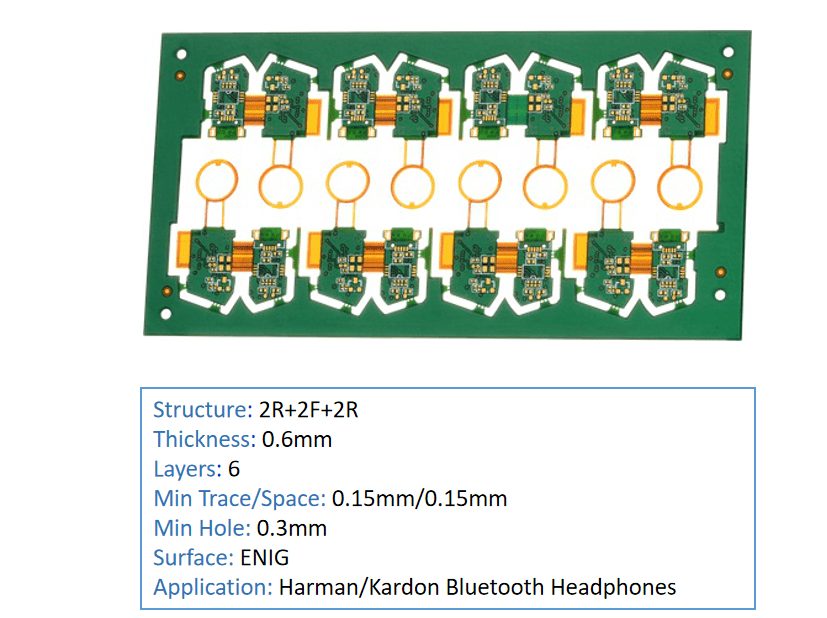

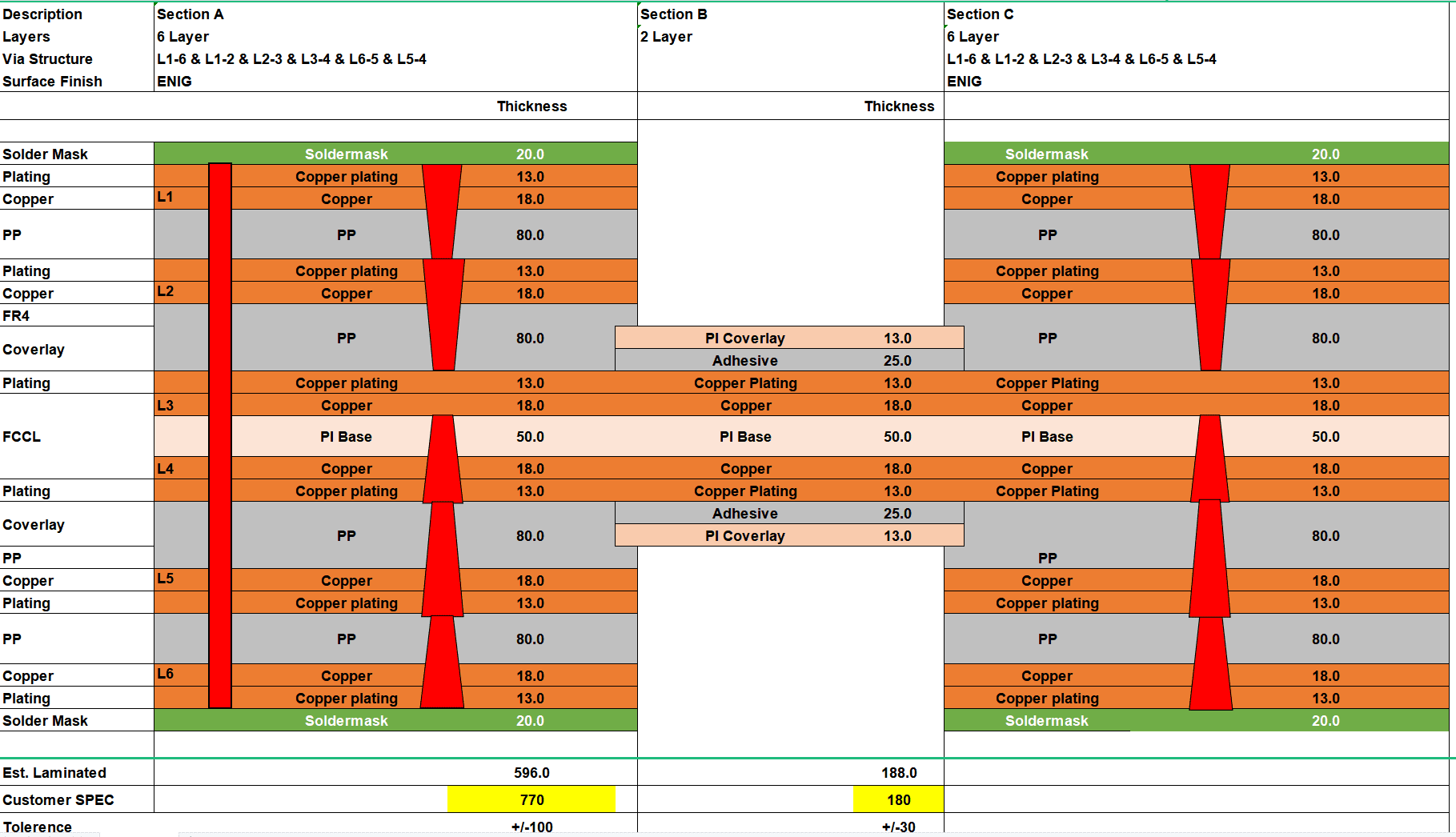

5 and 6 layers rigid flex PCBs are very common in rigid flex PCB design, especially at consumer electronics sector. Right rigid-flex Board is a perfect illustration.

This board is a 6 layer HDI rigid flex pcb. Its overall board thickness is 0.6mm. The finished copper thickness is 2 OZ. Green solde mask is in the rigid area and amber cover film is in flex area.

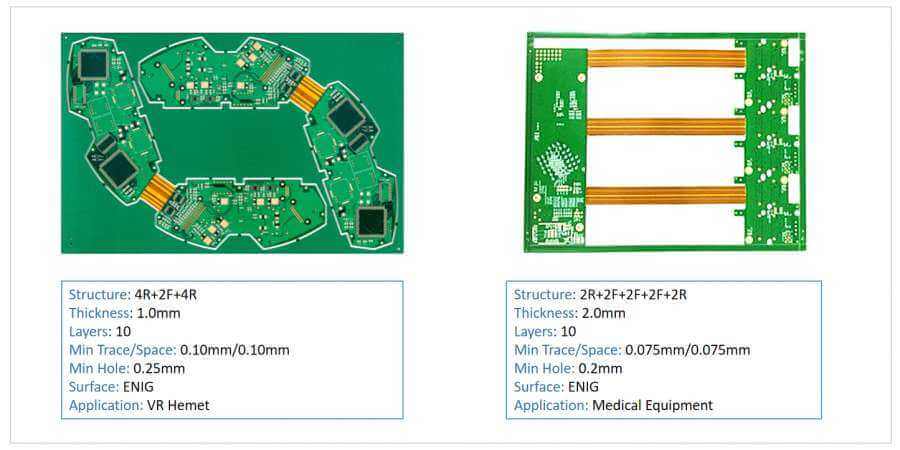

Medical industry used a lot rigid flex PCB due to its demand for higher connection reliability and smaller size. The 10 layers board below is just a great example.

It is with 2R+2F+2F+2F+2R stackup, 2.0mm final thickness. The Min trace width and space are the same-0.075mm, Min hole dimension is 0.2mm.

This stackup is designed for electrocardiogram (ECG/EKG) which requires high density interconnection.

Stacked microvias can save space and increase density, offer greater flexibility concerning the inner connections, better routing capacity and less parasitic capacitance.

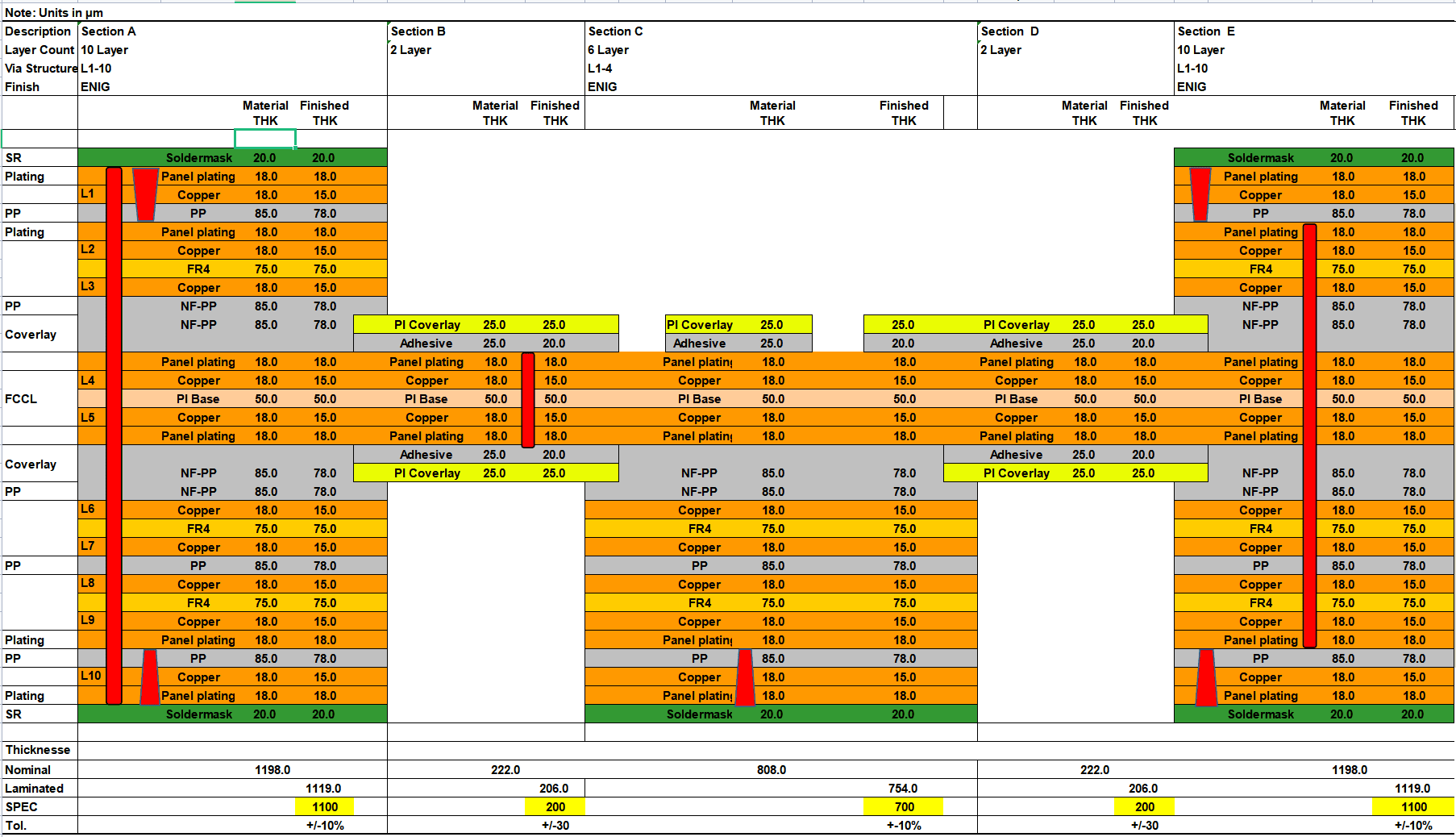

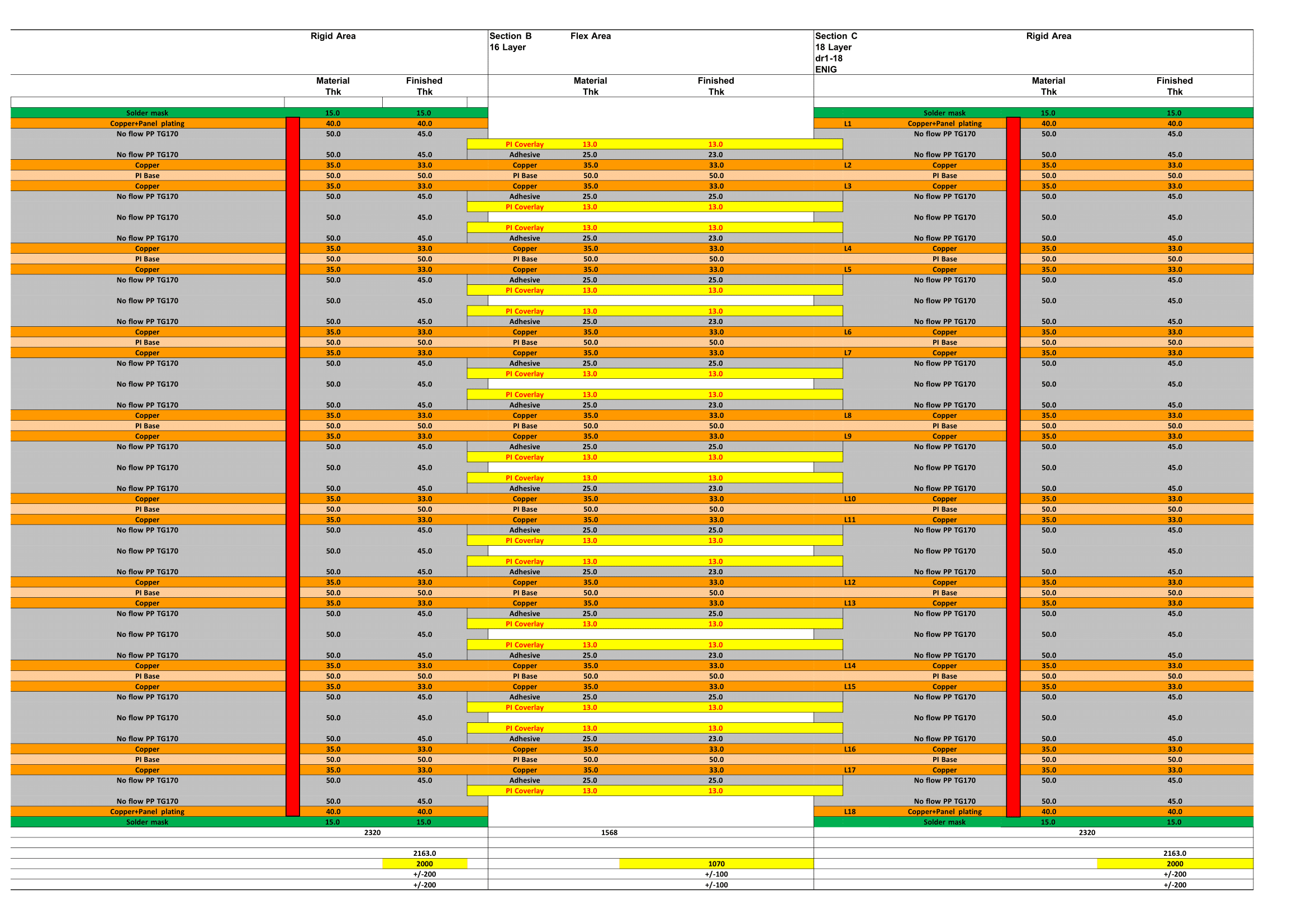

This stackup is created for a 10-layer rigid flex PCB that supports robotics application. It shows all the layer thickness, and drilling placement. There are buried vias in the FPC section and blind vias in the rigid section.

This stackup is created for a 10-layer rigid flex PCB that supports robotics application. It shows all the layer thickness, and drilling placement. There are buried vias in the FPC section and blind vias in the rigid section.

XPCB is a leading provider of fast turnaround flex PCB and rigid-flex PCB design and fabrication services. With years of expertise in this space, XPCB offers customers a fully integrated solution for flex and rigid-flex printed circuit board prototyping and production.

With XPCB’s quick-turn rigid flex PCB fab service, you can have your flex or rigid-flex PCB prototypes manufactured within 3 business days after your design is approved for production. This helps product designers and engineers accelerate their product development cycles by receiving physical prototype boards sooner to conduct testing and validation. No minimum order quantities apply, so you can order even a small number of flex PCB prototypes to test design concepts early in the process.

XPCB utilizes state-of-the-art flex and rigid-flex PCB fabrication equipment to mass-produce flexible circuits with micro sizes, tight tolerances and precise panelization. From thin to thick copper layers, rigid, flex and mixed components, XPCB can manufacture almost any flex and rigid-flex design. They regularly deliver boards as thin as 0.1mm with tight tolerances under 5 mils. XPCB employs stringent quality control processes to ensure quick-turn prototypes meet the same quality and reliability standards as higher volume production runs.

In addition to quick-turn prototyping, XPCB offers full-service flex and rigid-flex PCB manufacturing for volumes from 50 to 10,000+ panels. Customers can rely on XPCB for the entire process from design review and optimization to fabrication, testing, assembly and logistics. With multiple facilities, XPCB delivers flex PCBs globally within excellent lead times even for higher production volumes.

If you need quick prototypes for your next rigid-flex project, contact us today at [email protected]. Rely on one of the leading rigid-flex PCB manufacturers in China to elevate your product to the next level.

Increase the binding force of rigid-flex PCB

2mil Above Circuit Detection Scanning

Pretreatment of inner layer pressing

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve