Accelerate Your Product Development with Rapid Prototyping Assembly Services

Have an exciting new product idea but worried about the long lead times of traditional manufacturing? Then rapid prototyping assembly is the solution to get your innovative design to market as quickly as possible. This comprehensive guide will show you how rapid prototyping services can significantly compress your product development cycle while maintaining high quality.

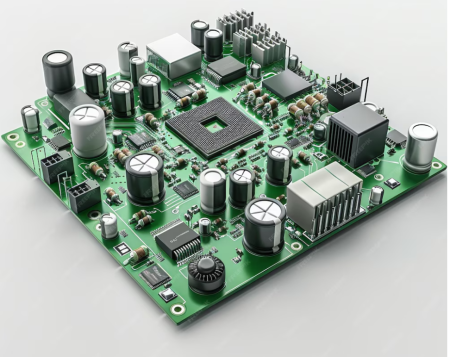

Streamline Your Design Validation With Printed Circuit Board Prototypes

A key early step in the product development process is validating the design through prototyping. Traditionally, this involved lengthy PCB fabrication times of 4-6 weeks. However, with quick-turn PCB assembly from companies like XPCB LIMITED, you can now get prototype printed circuits boards assembled in as little as 3 business days. This allows engineers to rapidly iterate their designs through multiple revision cycles in a fraction of the time. Faster design validation gets crucial feedback earlier and eliminates defects before moving to production.

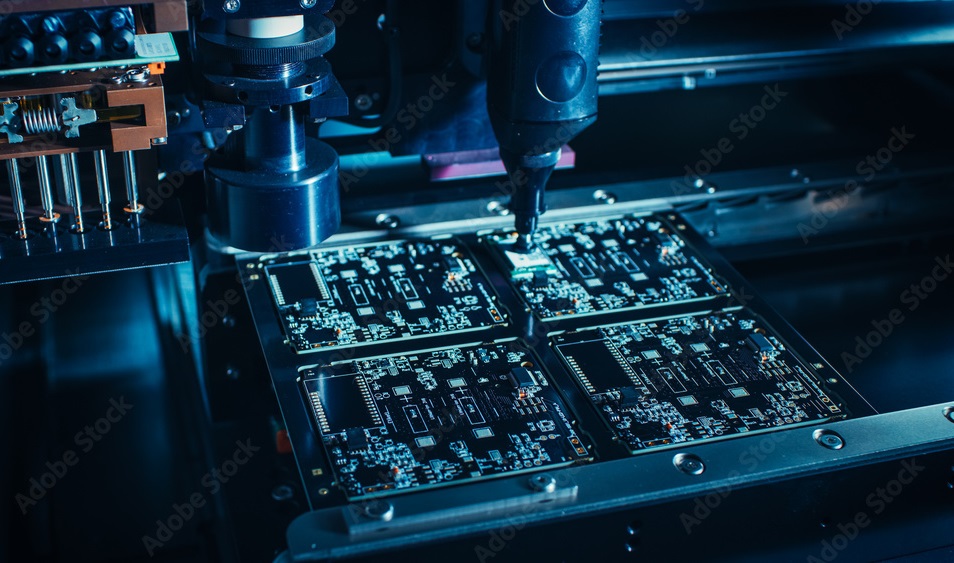

Accelerate Testing and Certification with Functional Prototypes

Once the initial PCB design is verified, incorporating other components allows assembling functional prototypes for comprehensive testing. This is vital for validating mechanical, electrical and firmware aspects together before tooling up for manufacturing. Contract manufacturers focused on rapid prototyping services are optimized to deliver these system level prototypes within 1-2 weeks using advanced SMT assembly lines. Their experience also helps navigate certification requirements more smoothly. Functional prototypes get products closer to market while meeting all compliance needs.

Tailor Precision Prototyping Services for Your Unique Needs

While quick-turn services offer standard fixed turnarounds, certain projects may require accelerated or customized schedules. Industry leaders like XPCB LIMITED understand every product has unique complexities and are very flexible. Their engineering expertise can advise the fastest path based on your specifications. Volume capabilities range from low to high quantities on both delivered prototypes as well as any on-going production needs after launch. Project managers meticulously plan each step to deliver right the first time on extremely tight deadlines.

Optimize Designs Faster with Fully Assembled Engineering Samples

As development progresses from schematics to prototypes, fully assembled engineering samples become crucial for form, fit and function testing before tooling. Contract manufacturers streamline this process with integrated supply chain management of custom PCBs and value-add assembly services. Customers provide Gerber files and BOMs to trusted partners focused on rapid delivery of assembled prototypes within 10 working days. Early reliability testing smoke out design weaknesses in a jiffy for constructively guiding design optimization ahead of formal production.

Accelerate Design Validation and Certification Cycles

Through optimal quick-turn services for prototypes at each stage, product development cycles compress tremendously. Engineers can iterate designs much faster based on assembly/test results, tightening design quality earlier. Prototypes help validate form factors, wiring sequences, manufacturability and mechanical/firmware integration speedily. This also frees up time for navigating applicable standards/regulations seamlessly in parallel. Faster certification cycles get innovative technologies to market without delays, giving companies a clear competitive edge.

Reduce Time-to-Market and Mitigate Risks with Early Prototyping

Getting products proven through prototypes in weeks vs months has tremendous commercial advantages. It minimizes time-to-market and associated opportunity costs. Early prototypes reveal design issues promptly for corrective action versus costly reworks at production stage. Customers also benefit from hands-on early evaluation of functionality, usability and applications to seed stronger initial demand. Overall risks are significantly reduced via rigorous upfront validation, building confidence for manufacturing scale-up and successful market launch on schedule. Projects progress more predictably towards go-to-market goals.

Achieve Scale with Smooth Transition from Prototyping to Production

Once initial prototypes prove out the design concept and gain early user feedback, it’s time for volume manufacturing ramp up. While quick-turn firms primarily serve prototyping needs, their quality abilities and flexibilities ease this transition smoothly. Customers achieve continuity by retaining the same manufacturer as production volumes scale up. This facilitates seamless knowledge transfer of design challenges addressed during prototyping stages directly into production-optimized processes. Manufacturers maintain rigorous standard operating procedures across low and high volume assembly to achieve consistent quality volumes customers can rely on.

Leverage Expertise of Global PCB Assembly Manufacturers

Industry pioneers in rapid prototyping assembly services deliver exceptional value due to their depth of experience from serving high-technology sectors worldwide for decades. Customers gain tremendous leverage from their continuously optimized assembly technologies, supply chain integrations and industry certifications. Manufacturing partnerships also benefit from global footprints to solve any logistic challenges. Dedicated project managers shepherd full turnkey solutions right from prototype design reviews and RFQ preparation to final product delivery on schedule against committed timelines and quality standards.

Accelerate Designs to Market Through Strategic Collaborations

Leading prototyping specialists promote open collaboration to maximally streamline the product development cycle. Their design centers worldwide offer co-innovation lab access and capabilities for electronic, mechanical and thermal profiling on customer boards. Select partners provide bundled prototyping services along with simulation, DFM analysis and quick-turn PCB fabrication for complete solutions. Others integrate seamlessly with developers via their various technology platforms and app programming toolkits. Strategic collaborations thus help accelerate products through all phases to market at the speed of ideas with minimum hassles.

Custom Prototyping Services Unlock the Power of Innovation

Forward-thinking OEMs and startups unlock exponential growth opportunities leveraging custom rapid prototyping services. These high-end solutions empower ambitious projects beyond standard offerings through highly flexible engineers. From exclusive non-recurring engineering to sophisticated multi-board assembly architectures – manufacturers accommodate any complexity with military-grade quality control towards accelerated timelines. Overall custom prototyping removes the constraints that innovation demands, empowering customers to take ambitious ideas from concept to commercialization at lightening speeds unheard before.

In Summary of prototype assembly

Rapid prototyping assembly services have revolutionized product development by compressing cycles significantly through faster design validation, iterations and certifications. Strategic partnerships with global leaders deliver complete quick-turn solutions leveraging joint expertise for superior quality. This guide highlighted how these services minimize risks, hasten time-to-market and fuel continual innovation. Overall, rapid prototyping empowers ambitious projects from ideation through market launch at unprecedented speeds for transformative commercial advantages.