- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

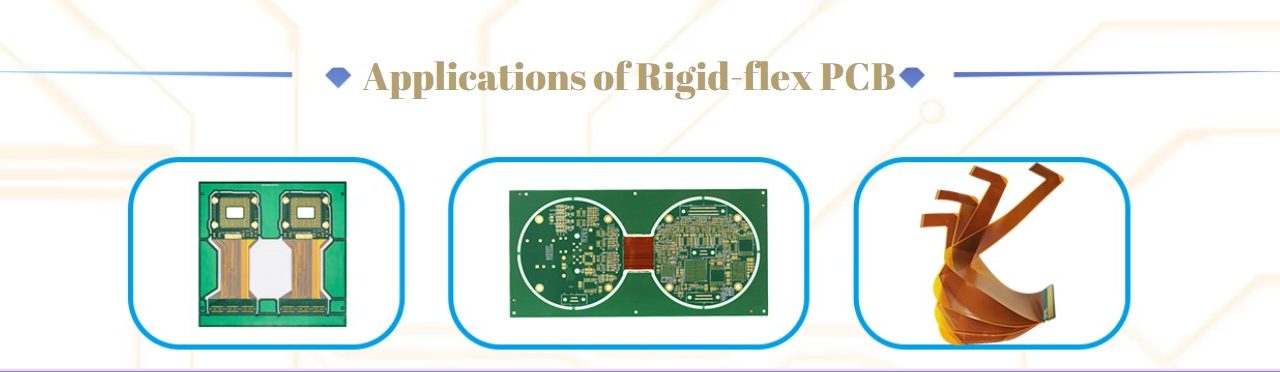

Rigid-flex PCBs have revolutionized electronic design and manufacturing, offering unparalleled flexibility and functionality across various industries. In this blog post, we’ll explore the applications and advantages of rigid-flex PCBs, supplemented by real customer stories that highlight their transformative impact.

Rigid-flex PCBs combine rigid and flexible circuitry elements, providing a versatile solution for complex electronic designs. These PCBs offer enhanced reliability, reduced assembly complexity, and optimized space utilization, making them ideal for a wide range of applications.

A renowned automotive manufacturer sought our expertise at XPCB Ltd to enhance the performance and reliability of their advanced driver-assistance systems (ADAS). By incorporating rigid-flex PCBs into their design, we facilitated the development of a compact and efficient electronic assembly that contributed to improved vehicle safety and efficiency.

Rigid-flex PCB technology is transforming the consumer electronics industry by offering compact and lightweight design solutions, enhancing reliability and durability, enabling innovative features and functionality, and supporting cost-effective manufacturing processes. By leveraging the unique advantages of rigid-flex PCBs, manufacturers can create differentiated, high-quality, and sustainable consumer electronic products that meet evolving market demands, exceed customer expectations, and drive success in today’s competitive landscape.

Realizing the potential of rigid-flex PCBs, a medical device manufacturer partnered with us to design a compact and lightweight wearable health monitor for patients with chronic conditions. By integrating rigid and flexible circuitry, we developed a PCB assembly that prioritized patient comfort, reliability, and performance, showcasing the versatility and innovation of rigid-flex PCB technology.

In the aerospace and defense sectors, rigid-flex PCBs are integral to mission-critical systems. For example, a leading aerospace company approached us at XPCB Ltd to develop a rigid-flex PCB solution for their satellite communication systems. By leveraging our expertise in rigid-flex PCB fabrication, we delivered a reliable and robust solution that withstood extreme conditions, including temperature fluctuations and mechanical stresses.

Rigid-flex PCB technology has gained significant traction in the electronics industry due to its numerous advantages over traditional PCB solutions. Below, we delve into the detailed advantages that rigid-flex PCB technology offers, emphasizing its transformative impact on electronic design and manufacturing.

Rigid-flex PCBs enable designers to create intricate and complex configurations by integrating both rigid and flexible sections into a single assembly. This allows for the development of innovative solutions that are not feasible with traditional PCB technologies, facilitating the design of compact, lightweight, and multifunctional electronic devices.

Rigid-flex PCB technology supports 3D integration by allowing components to be mounted on both rigid and flexible sections, enabling designers to optimize space utilization and create unique form factors. This flexibility enables the development of advanced electronic systems with reduced footprint and enhanced functionality.

Rigid-flex PCBs minimize potential points of failure by eliminating the need for interconnects and connectors, reducing mechanical stress, and enhancing overall reliability. This robust construction withstands environmental factors, vibrations, and thermal stresses, ensuring long-term performance and durability in demanding applications.

Rigid-flex PCB technology offers superior signal integrity by minimizing electromagnetic interference (EMI), signal loss, and cross-talk between components. This optimized performance ensures consistent and reliable operation, particularly in high-frequency and high-speed applications where signal integrity is critical.

Rigid-flex PCBs enable designers to maximize space utilization by integrating multiple functions into a single assembly, eliminating the need for additional components, connectors, and wiring. This compact and lightweight design reduces overall size, weight, and complexity, contributing to enhanced portability and efficiency in electronic devices.

Rigid-flex PCB technology simplifies assembly processes by reducing the number of components, connectors, and interconnects required, minimizing manual labor, and potential human errors. This streamlined assembly process accelerates time-to-market, reduces production costs, and enhances overall manufacturing efficiency.

While rigid-flex PCBs may involve higher initial manufacturing costs due to complex design considerations and specialized materials, they offer long-term cost efficiency by reducing assembly complexity, minimizing maintenance requirements, and extending product lifecycle. This cost-effective solution delivers superior value by optimizing performance, reliability, and durability in diverse applications.

Rigid-flex PCB technology supports scalability and adaptability by facilitating design modifications, upgrades, and customization without compromising performance or reliability. This flexibility enables manufacturers to meet evolving market demands, technological advancements, and customer requirements, ensuring long-term success and competitiveness in dynamic industries.

Increase the binding force of rigid-flex PCB

2mil Above Circuit Detection Scanning

Pretreatment of inner layer pressing

Rigid-flex PCBs continue to redefine electronic design and manufacturing, offering unparalleled versatility, reliability, and efficiency across various industries. Through real customer stories and partnerships, we’ve highlighted the transformative impact of rigid-flex PCBs in aerospace, medical devices, automotive electronics, and consumer electronics, showcasing their potential to drive innovation and excellence in today’s competitive market landscape.

If you’re considering leveraging the benefits of rigid-flex PCBs for your next project, partnering with an experienced manufacturer like XPCB Ltd can make all the difference. Contact us today to explore how rigid-flex PCBs can transform your designs and deliver unparalleled value for your electronic innovations.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve