- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

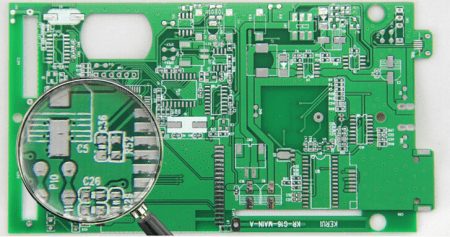

The PCB process edge refers to the part added on both sides or four sides of the PCB, which is not part of the PCB board and needs to be removed after the production is completed. The main function is to assist in the production of plug-in boards, reserve the track transmission position during SMT processing, and place the long blank board edge set by the imposition Mark point to ensure smooth completion.

In the quotation production process, PCB manufacturers often confirm with customers whether the PCB board needs to add process edges, and how much the process edge width is. As for whether the circuit board needs to add process edges, it depends on the design structure of the circuit board. Whether the production is done manually or by machine equipment can be considered in many ways.

Finally, it is necessary to increase the process edge of the circuit board. The width of the conventional process edge is 5mm or 8mm (the customer may also specify it according to the actual situation)

Image 1: Basic Knowledge of PCB process edge

The flatness of the PCB process edge is also an important part of the PCB production process that needs to be controlled. When removing the process edge of the circuit board production, it is necessary to ensure that the process edge is smooth, especially for the circuit board with high assembly accuracy. Any uneven edge will lead to offsetting the mounting hole, which will inconvenience the subsequent PCBA assembly and processing.

Because the PCB process will consume more PCB plates, it will increase the overall manufacturing cost of printed circuit boards. Therefore, when designing the PCB process edge, it is necessary to balance economy and manufacturability. For some special-shaped circuit boards, the original 2 or 4 PCB process edges can be simplified by cleverly splicing the board, and the track width of the SMT placement machine can be fully considered.

The purpose of reserving the process side is to clamp the PCB board and flow through the placement machine. In the assembly process, the electronic components that are too close to the track side are sucked up by the suction nozzle of the SMT placement machine and placed on the PCB board, which is prone to collision phenomenon, resulting in the inability to complete the production process.

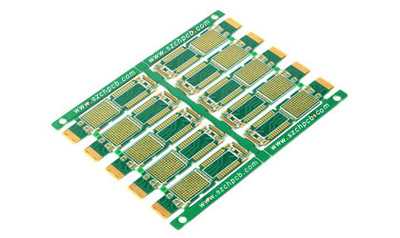

Image 2: PCB assembly service

A certain process edge must be reserved for some plug-in components to avoid preventing similar phenomena when passing through wave soldering. The minimum PCB process edge is 0mm, which is limited to rectangular PCB or square PCB on the board edge, and the minimum PCB process edge is 3mm-5mm for some special special-shaped PCB circuit boards.

The process edge of the PCB board refers to the processing technology of the edge of the circuit board, which has the following advantages:

Aesthetics: The process edge of the board can increase the aesthetics of the circuit board, make the circuit board look more neat and regular, and also improve the grade of the product.

Prevent flashing: The process edge of the circuit board can effectively prevent the edge of the PCB from flashing, and reduce the damage and defects of the circuit board in the processing process.

Improve the strength of the PCB: The process edge of the circuit board can increase the strength of the PCB and reduce the deformation and fracture of the circuit board during use.

Image 3: The rigid PCB process edge

Easy processing and installation: The process edge of the circuit board can provide the convenience of installation and processing for the circuit board, making the circuit board easier to be processed and used.

Improve product quality: The process edge of the circuit board can improve the quality and stability of the product and reduce the probability of failure of the circuit board during use.

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve