- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

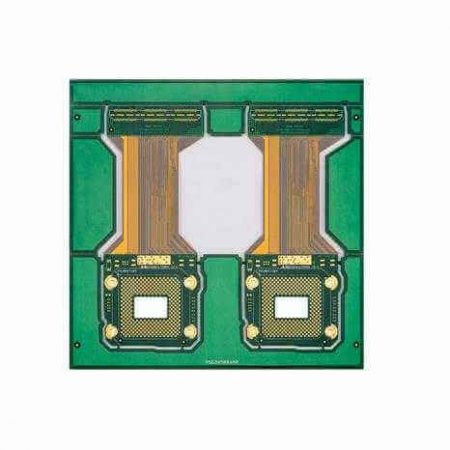

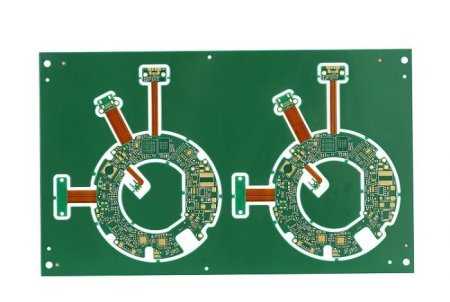

Rigid-flexible PCB is a hybrid printed circuit board that combines a flexible circuit board and a rigid circuit board. It combines the advantages of flexible and rigid circuit boards to meet the requirements in applications where space is constrained or high-density integration is required.

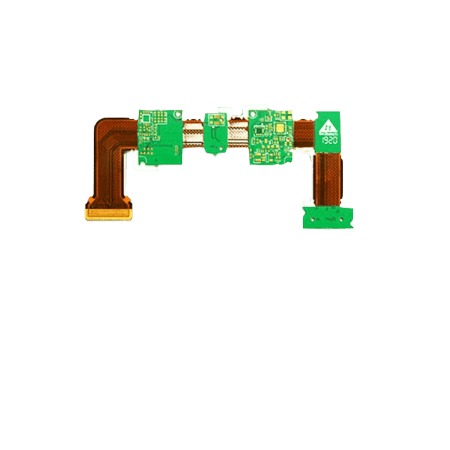

Flexible circuit boards are made of flexible substrates, such as polyimide film, that can be bent and folded, and can accommodate a variety of shapes. Rigid circuit boards are made of a rigid substrate, such as fiberglass, and are typically used to support and hold electronic components.

Rigid-flexible PCBs are usually formed by flexible circuit boards and rigid circuit boards connected to form a single unit. By using this structure, the advantages of flexible and rigid boards can be combined when needed, allowing for greater design flexibility and integration. For example, in some applications, flexible circuit boards can be used to connect different rigid circuit boards, enabling more complex circuit layouts. In other applications, flexible circuit boards can be used to achieve curved or curved shapes to accommodate specific space constraints.

Rigid-flex PCBs are commonly used in high-end electronic devices such as smartphones, tablets, and laptops. Due to its design flexibility and reliability, rigid-flex PCB has also become one of the emerging printed circuit board technologies.

Design: Designers need to design the circuit layout and shape of the rigid-flex PCB according to the requirements and space constraints of the electronic product.

Manufacturing rigid circuit boards: The manufacturing process for rigid circuit boards is similar to the traditional printed circuit board manufacturing process, including steps such as cutting, drilling, copper plating, and more.

Fabrication of flexible circuit boards: The manufacturing process of flexible circuit boards requires the use of special substrates and technologies, including the coating, exposure, and etching of thin film materials.

Circuit connection: The rigid circuit board and the flexible circuit board are connected by soldering, gluing, or plugging to form a rigid-flex PCB.

Testing and quality control: Testing and quality control of rigid-flex PCBs to ensure that they meet the requirements and standards of electronic products.

Design flexibility: Rigid-flex PCBs can enable more complex circuit layouts and shapes to meet the requirements and space constraints of different electronic products.

High-density integration: Rigid-flexible PCBs can achieve a higher level of circuit integration without increasing the size of the board.

Reliability: Rigid-flex PCBs can be used to connect rigid and flexible circuit boards in a variety of ways, thereby enhancing the stability and reliability of the circuit board.

Cost savings: Rigid-flex PCBs can reduce the number of assembly steps and parts in electronic products, thereby saving costs and improving production efficiency.

In conclusion, rigid-flexible PCB is a powerful, flexible design, and highly reliable printed circuit board technology, which has become an indispensable part of high-end electronic products.

But at the same time, there are also some challenges and limitations in rigid-flexible PCB, such as high manufacturing costs, complex manufacturing processes, and difficult maintenance. Therefore, factors such as the actual needs and manufacturing costs of electronic products need to be fully considered when choosing rigid-flex PCBs.

With the continuous development and popularization of electronic products, the combination of hardware and software PCB technology will also be continuously improved and applied. In the future, the combination of hardware and software PCB will play a role in a wider range of fields, such as smart wearable devices, smart homes, medical equipment, etc. At the same time, the promotion and development of rigid-software PCB technology also needs to continuously promote innovation and improve technology to meet the needs and challenges of different fields.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve