- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

A rigid PCB prototype is a functional sample of a printed circuit board (PCB) that is created before manufacturing the final product. It is an essential step in the PCB design process as it allows designers to test and verify the functionality of their design before mass production. PCB prototypes can be created using various methods like breadboarding, solderless breadboarding, or using PCB design software to create a virtual prototype. Once the prototype is created, it is tested for functionality and any necessary changes are made before proceeding to mass production. Rigid PCB prototypes can save time and money by identifying and correcting design flaws early in the process.

PCB (Printed Circuit Board) manufacture involves the process of designing, fabricating, and assembling PCBs for electronic devices.

Image 2: X-RAY Driling Machine

The process typically involves the following steps:

Design: The first step in PCB manufacture is the design of the circuit board. This involves using specialized software to create a schematic of the circuit and then laying out the components and traces on the board.

Fabrication: Once the design is complete, the PCB is fabricated. This involves transferring the design onto a copper-clad board and then using chemical etching to remove the copper in areas where there should be no conductive traces.

Drilling: After the copper has been etched away, the board is drilled to create holes for the components and vias (connections between different layers of the PCB).

Plating: After drilling, the board is plated with a thin layer of metal (usually copper) to create the conductive traces.

Soldermask: A solder mask is applied to the board to protect the exposed copper and prevent solder bridges from forming between the traces.

Silkscreen: A silk screen is applied to the board to label the components and to indicate the polarity of the components.

Assembly: The final step in PCB manufacture is the assembly of the components onto the board. This can be done manually or using automated equipment.

Overall, the PCB manufacturing process is complex and requires high expertise and precision to ensure that the final product is reliable and functional.

Image 2: PCB prototype service

PCB test is the process of checking the functionality and reliability of a printed circuit board (PCB) before it is used in a device or product. PCB testing involves several steps, including visual inspection, electrical testing, and functional testing of the PCB. The purpose of PCB testing is to ensure that the board meets the required specifications and functions correctly in the final product. PCB testing can be done through manual or automated methods, depending on the complexity of the board and the testing requirements.

Testing can be done at various stages of the PCB manufacturing process, such as after the board is fabricated, after components are attached, and after final assembly.PCB testing is important because it helps to identify any faults or defects in the board before it is used in a product, which can prevent costly errors and reduce the risk of product failure. PCB testing can also help to improve the quality of the final product by identifying design flaws or manufacturing issues that may affect performance or reliability.

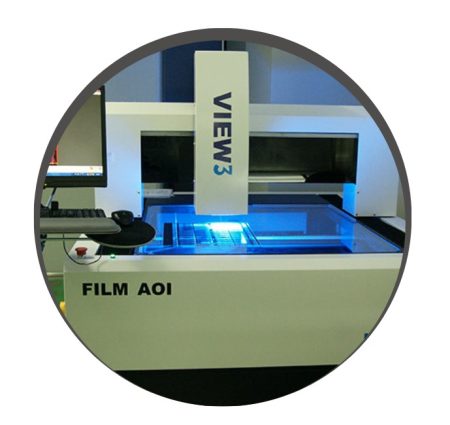

PCB testing can be done using a variety of tools and techniques, including visual inspection, automated optical inspection (AOI), quality and reliability of the PCB, testing is also an important part of meeting regulatory requirements and industry standards for electronic devices and products. Overall, PCB testing is an essential step in the manufacturing process that can help to ensure the success of a product and the satisfaction of customers.

Image 3: Prototype and small run specialist

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve