- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Selecting the right SMT (Surface Mount Technology) factory is crucial for the success of your electronics manufacturing project. Here are key factors to consider when making your choice:

Industry Experience: Look for factories with a proven track record in SMT assembly. Check their years of operation and expertise in your specific type of product.

Client Testimonials: Seek reviews or case studies from previous clients to assess their satisfaction with the factory’s services.

Certifications: Verify if the factory has relevant certifications such as ISO 9001, IPC-A-610, or other quality standards.

Quality Control Processes: Inquire about their quality control measures, including testing procedures, inspection protocols, and defect rates.

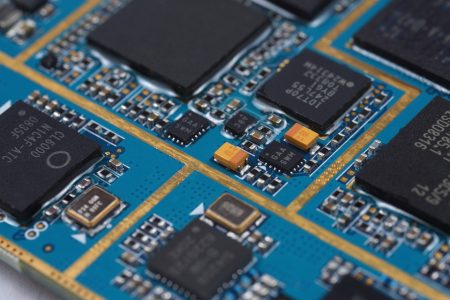

Production Capabilities: Assess if the factory can handle your specific production volume and complexity. Check for advanced machinery like pick-and-place machines, reflow ovens, and automated optical inspection (AOI) systems.

Technology and Innovation: Determine if they invest in the latest technologies and processes, which can enhance efficiency and product quality.

Transparent Pricing: Request detailed quotes and understand the pricing structure. Be wary of factories that offer significantly lower prices without clear justification.

Cost Factors: Consider additional costs such as tooling, setup fees, and shipping, which can impact your overall budget.

Production Lead Times: Ensure the factory can meet your required timelines. Ask about their capacity to handle urgent orders or fluctuations in demand.

Flexibility: A good factory should be adaptable to changes in orders, whether it’s scaling up production or making design adjustments.

Language and Time Zone: Ensure effective communication channels are in place. Language barriers can lead to misunderstandings, so choose a factory that can communicate fluently in your preferred language.

Customer Support: Assess their responsiveness and willingness to assist with any inquiries or issues during production.

Proximity: Consider the factory’s location concerning your headquarters. Closer factories can reduce shipping costs and lead times.

Logistics and Supply Chain: Evaluate the factory’s access to suppliers for components and materials, which can impact production efficiency.

Warranty and Support: Understand their warranty policies and how they handle post-production support, including repairs or replacements for defective products.

Long-term Partnership: Look for a factory that values long-term relationships and is committed to your ongoing success.

Selecting the right SMT factory requires careful consideration of multiple factors. By thoroughly evaluating each potential partner based on these criteria, you can make an informed decision that aligns with your project needs and business goals. Taking the time to conduct due diligence will ultimately lead to a smoother production process and higher-quality products.

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limitedbe your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve