- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

SMT manufacturing technology (Surface Mount Technology) is an electronic manufacturing technology that uses surface mount technology to attach electronic components directly to the surface of a printed circuit board (PCB). Compared with traditional plug-in PCB assembly technology, SMT manufacturing has higher production efficiency, smaller size, lower cost, and better performance. In the modern electronics industry, SMT has become a mainstream manufacturing technology.

High production efficiency: Compared with the traditional plug-in assembly technology, SMT manufacturing technology has higher production efficiency.

Small size: Since SMT technology can directly attach electronic components to the surface of a printed circuit board (PCB), components can be smaller in size.

Low cost: The production cost of SMT manufacturing technology is relatively low because it can produce more electronic components in a shorter time.

Good performance: The electronic components produced by SMT technology are also better in terms of performance than traditional plug-in assembly technology.

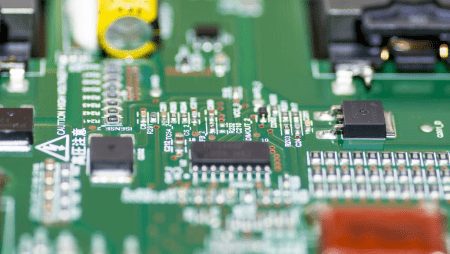

Image 1: PCB assembly service

High requirements for PCB board surface: SMT manufacturing technology has very high requirements for the quality of PCB board surface, if the board surface is poor, it will lead to poor installation of electronic components.

Difficult to repair: Since the electronic components are directly attached to the PCB board, if the components need to be repaired or replaced, professional equipment and technology are required.

High requirements for the environment: SMT manufacturing technology requires the use of some chemicals, and the requirements for the environment are relatively high.

Image 2: SMT manufacture technology

The circuit board produced by the PCB board factory can not be used directly, and various components need to be soldered on the circuit board before it can operate normally.

(1) Different surface processes, resulting in different reasons why the PCB pad is not tin, take the immersion gold plate as an example: check whether the PCB pad has oxidation and discoloration before soldering, if there is, it needs to be returned to the board factory for cleaning and baking.

(2)The reasons why the tin spray board is not tin or the tin is not full are:

a: check whether the PCB board and the solder paste are both leaded or lead-free tin before soldering, and 100% of the tin cannot be guaranteed to be full due to different compositions;

b: Tin spray oxidation or tin spray thickness is too thin, or due to the quality of the PCB itself is not tin at all, it can be improved by replacing solder paste or washing steel mesh.

Image 3: Quality Standard for SMT manufacturing technology

Based on the advantages and disadvantages of SMT technology mentioned in the context, the development prospects of PCB assembly technology are positive but also face challenges. While SMT technology offers higher production efficiency, smaller component size, lower production cost, and better performance, it also requires high-quality PCB surfaces, poses difficulties for repairs and replacements, and demands high environmental standards.

Therefore, PCB packaging needs to balance the benefits and drawbacks of SMT technology and explore new methods to improve its quality, reliability, and sustainability. With the growing demand for electronic devices and the trend towards miniaturization, PCB packaging is expected to continue to evolve and innovate in the future.

Image 4: The PCBA by SMT manufacturing technology

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve