- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

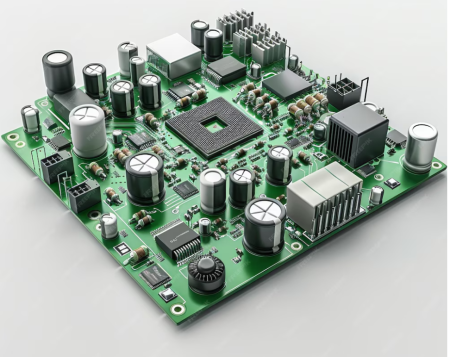

When manufacturing printed circuit boards (PCBs), engineers have two primary component attachment options: surface mount technology (SMT) or through-hole technology (THT). Both methods present tradeoffs that must be carefully weighed based on a project’s specific requirements. This comprehensive guide examines the key differences between SMT and THT assemblies to help electronics designers select the most suitable approach.

As its name implies, SMT assembly involves placing electronic components directly onto the surface of a PCB. Components have leads that are soldered directly to pads on the surface rather than passing through holes drilled in the board. This allows for a significantly smaller footprint and denser packing of components compared to traditional THT.

The minimized space requirements of SMT make it well-suited for applications where board real estate is at a premium, such as cell phones, tablets, and other compact devices. By reducing component sizes and increasing circuit density, SMT assembly enables the creation of ever-smaller electronics. It is now the mainstream assembly technique used by the majority of consumer electronics manufacturers.

However, the tiny surface-mounted components of SMT designs require specialized high-precision placement equipment during assembly. Even minuscule deviations in position can cause issues. Additionally, SMT components are more difficult for technicians to handle and repair by hand compared to their through-hole counterparts if issues do arise.

In contrast to SMT, THT assembly involves physically inserting electronic component leads through drilled holes in a PCB. The leads are then soldered on the opposite side to electrically connect the parts to the board.

While less dense than SMT, THT still remains a trusted option today for applications requiring reliability, easy repair, or specialized components that are not available in surface-mount packages. It is also well-suited to initial breadboarding and prototyping stages where circuit designs may undergo frequent changes and adjustments before being committed to a compact permanent form.

The through-hole design of THT components makes them robust, visually inspectable, and repairable by hand without specialist tools. Leads can be easily desoldered and resoldered during testing and debugging. As such, THT excels for educational, industrial, and other applications where quick modification is important or automated assembly may not be feasible.

When selecting between SMT vs. THT, the primary factors to consider are:

SMT assemblies allow for dramatically smaller board sizes and higher component density thanks to surface mounting. THT consumes more space due to through-hole leads and larger component footprints.

SMT places higher demands on assembly equipment for micro-scale placement and soldering accuracy. THT can be done largely by hand.

THT components have leads that are visually inspectable and manually repairable. SMT parts are not as easily accessible.

SMT is best for high-volume production, while THT excels in prototyping and building before committing to a stable design.

Certain parts may only be available in one mounting style depending on your needs. Check distributor stock.

SMT assemblies generally require pricier assembly equipment but facilitate smaller boards and higher integration.

Weighing these factors will help determine the optimal mounting technique. But fear not, as experts like XPCB Limited can successfully execute both SMT and THT assemblies to suit your specific requirements.

As a premier PCB assembly company based in Shanghai, XPCB Limited has extensive experience with both SMT and THT processes. Their assembly facilities contain industry-leading placement, inspection, and soldering systems to handle any board design. Highly-trained technicians then utilize lean manufacturing principles for efficient production.

XPCB‘s SMT capabilities include:

– Pick and place machines with accuracy down to 50 microns

– Reflow ovens with 299-zone temperature control

– Automatic optical inspection (AOI) and x-ray (AXI) for 100% defect analysis

– Additional hand soldering as neededMeanwhile, the company’s through-hole assembly services cover:

– Manual insertion and soldering on rework stations

– Inspection through microscopy and continuity testing

– Conformal coating application

– Rigorous quality control throughout

By leveraging dual SMT/THT competencies, XPCB delivers quick turnaround and low manufacturing minimums. Most importantly, clients benefit from the company’s fanatical focus on quality, reliability and customer service – making them a trusted partner from prototype to mass production.

Whether using SMT or THT, finding an assembly partner with process expertise, robust QA, and competitive pricing is paramount. Otherwise, inefficiencies or defects could undermine your beautiful PCB layout designs and hurt your bottom line.

Conduct due diligence to verify a candidate’s capabilities, scale, certifications, and track record. Consider total landed costs including duties vs just unit pricing. Understand turnaround times, MOQs, and any unique needs for your project.

With the right EMS provider, your circuit boards can be transitioned smoothly and cost-effectively from prototype to volume manufacturing – setting your product up for market leadership. Selecting XPCB means peace of mind from concept to mass production thanks to their SMT and THT assembly prowess.

In closing, both SMT and THT assembly strategies play essential roles within the electronics industry. Rather than viewing them as competitors, a balanced perspective recognizes how they beautifully complement one another based on specific phase-of-life and form-factor needs.

With expertise in both surface mount and through-hole processes, assemblers like XPCB Limited empower designers to seamlessly integrate the optimal mounting approach – or blend techniques creatively within a single project as required. Let proven assembly professionals handle the manufacturing minutiae so you can focus fully on innovation.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve