- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

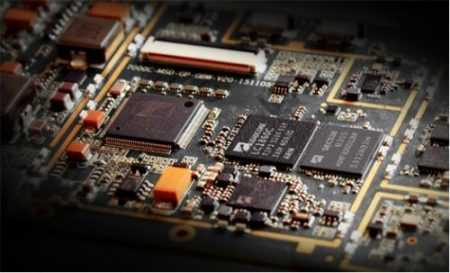

Manual welding shall follow the standards of small to large, low to high, type and batch welding, first welding chip resistors, chip capacitors and crystal triodes, then welding small chip components and large chip components, and finally welding inserts.

When welding chip components, the width of the selected soldering iron tip shall be consistent with the width of the components. If it is too small, it is difficult to locate during assembly and welding.

When welding SOP, QFP, PLCC and other components with pins on both sides or four sides, you must first weld several positioning points on both sides or four sides, and carry out drag welding for the remaining feet after carefully checking that each foot is consistent with the corresponding pad. The speed of drag welding shall not be too fast. It is OK to drag up and down one tin spot in 1s.

After welding, use a 4 ~ 6 times high-power magnifying glass to check whether there is bridging between tin dots. Where there is a bridge, you can use a brush to dip a little flux and then drag it again. The welding at the same position shall not exceed 2 times continuously. If it is not welded at one time, it shall be welded after it is cooled.

When welding chip components, a layer of solder paste is evenly coated on the pad, which can not only infiltrate and facilitate the soldering of tin spots, but also greatly facilitate the maintenance work and improve the maintenance speed.

The two most important processes for successful maintenance are pre preheating before welding and cooling after welding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve