- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In today’s fast-paced electronics market, efficiency, quality, and time-to-market are crucial for staying competitive. One of the best ways for companies to achieve these goals is through the use of turnkey PCB assembly (PCBA) and surface-mount technology (SMT) services. These services provide a comprehensive solution, handling every step of the PCB assembly process, from design to the final product, ensuring seamless production. One company that stands out in offering these solutions is XPCB, a leader in the field of PCB manufacturing and assembly. In this blog, we’ll explore how XPCB’s turnkey PCBA and SMT services can streamline your production process, improve product quality, and reduce costs.

Turnkey PCBA services refer to a complete solution that includes all aspects of the PCB assembly process, from the initial design to the final assembled product. When you choose a turnkey PCBA service, you are outsourcing the entire process to a single supplier who manages everything on your behalf. This includes:

XPCB’s turnkey PCBA service takes care of all these steps, allowing you to focus on your core business while they handle the complexities of PCB assembly

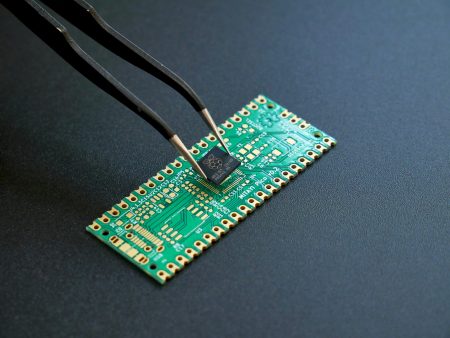

Surface-mount technology (SMT) is a method of mounting electronic components directly onto the surface of the PCB. Unlike traditional through-hole technology (THT), where components are inserted into holes in the board, SMT components are placed directly on the surface and soldered in place. SMT offers several advantages:

XPCB specializes in SMT assembly, using advanced equipment and techniques to ensure precision and quality in every board they assemble.

One of the primary advantages of choosing XPCB’s turnkey services is the simplification of project management. Traditionally, a company might need to manage several different suppliers for PCB fabrication, component sourcing, assembly, and testing. With XPCB’s one-stop solution, you only need to communicate with a single point of contact throughout the entire process. This reduces the complexity of managing multiple vendors and allows for better coordination and quicker response times.

Speed is critical in the electronics industry. By partnering with XPCB, you can significantly reduce the time it takes to bring your product to market. The streamlined nature of the turnkey service eliminates delays between design, prototyping, and production. XPCB’s SMT capabilities further accelerate production by enabling faster component placement and soldering, which results in quicker turnaround times for the finished product.

With multiple suppliers and different stages of production, there is always a risk of errors, such as incorrect component sourcing, assembly mistakes, or manufacturing defects. XPCB’s turnkey service minimizes these risks by consolidating the entire process under one roof. Their experienced engineers and technicians ensure that each step of the process is done to the highest standards, reducing the likelihood of mistakes and ensuring the final product meets your specifications.

Outsourcing your PCBA needs to XPCB can lead to significant cost savings. By handling everything in-house, XPCB can achieve economies of scale, reduce overhead, and streamline the production process. Additionally, their expertise in SMT assembly allows them to optimize component placement and material usage, which can further reduce costs. The consolidated service also eliminates the need for multiple contracts and vendors, simplifying accounting and billing processes.

XPCB is committed to providing high-quality PCBA and SMT services. They use advanced inspection and testing techniques to ensure that each PCB is free from defects and operates as expected. XPCB’s quality control procedures include automated optical inspection (AOI), functional testing, and X-ray inspection for verifying hidden layers and vias. By adhering to strict quality standards, XPCB ensures that your final product is reliable and meets industry specifications.

Every project is different, and XPCB understands that flexibility is key to meeting the unique needs of their clients. Whether you need low-volume production for prototyping or large-scale manufacturing for mass production, XPCB can accommodate your requirements. Their customization options allow you to adjust the design, components, and assembly process to best suit your product’s specifications. This level of flexibility makes XPCB an excellent partner for a wide range of industries, including consumer electronics, automotive, telecommunications, and medical devices.

Managing the supply chain is one of the most challenging aspects of PCB production. XPCB simplifies this by handling the procurement of materials and components, ensuring that everything required for production is readily available. With their established relationships with component suppliers and their efficient inventory management, XPCB can reduce lead times and ensure that components are sourced at competitive prices.

In today’s competitive electronics market, streamlining production is essential for success. XPCB’s turnkey PCBA and SMT services offer a comprehensive, efficient, and cost-effective solution that can help you meet your production goals while maintaining high quality. By outsourcing your PCB assembly needs to XPCB, you can save time, reduce costs, and minimize errors, all while benefiting from the expertise and advanced technology that XPCB provides. Whether you are developing a new product or scaling up production, XPCB is the partner you need to take your business to the next level.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve