- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

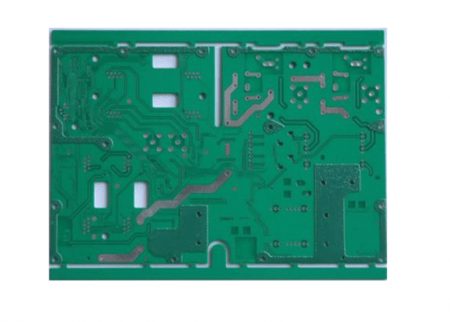

I believe that customers who have processed PCB circuit boards understand that when producing PCB circuit boards in batches, PCB prototyping is required before mass production. Circuit board prototyping is not only to understand the quality response of the product in advance, but also to reduce the defects in formal production. Therefore, PCB prototyping with guaranteed quality in advance is an indispensable link. Of course, the two parties must communicate the details and specific parameters in-depth before the prototyping, in order to promote the successful prototyping and lay the foundation for subsequent production. Let’s work with the editor of XPCB Limited to understand the purpose of prototyping:

Effective PCB prototyping before production can also clearly understand the strength of the circuit board manufacturers, especially the manufacturers that the two parties have not cooperated before. It can determine the strength level of the circuit board manufacturers in production through the prototyping. Only the circuit board manufacturers with equivalent ability and meeting the standard requirements in processing technology can better meet the requirements of long-term cooperation and high-quality processing and production of PCB boards.

2. It can reduce the defect rate during the production of large-scale PCB circuit board products

Usually the PCB board processing and production volume is relatively large, in order to ensure that mass production goes smoothly without quality problems and reduce the defect rate, it is very necessary to carry out the circuit board prototyping processing before production. After all, the processing of PCB boards needs to go through complicated processing procedures, and no errors can occur in every procedure or processing link. After successful prototyping, professional technicians will effectively test the samples. After passing various professional tests, it can be mass produced only after it is determined that there is no problem.

PCB prototyping is also to understand the performance and functional response of new products in advance. Through prototyping, we can effectively lay a good foundation for future mass production, calculate the corresponding material cost, and optimize the deficiencies in advance. These need to be effectively handled in the prototyping link to reduce various unexpected problems in mass production.

It can be seen that it is very necessary to carry out PCB prototyping before formal production, which is also the first step of successful cooperation with processing enterprises. Therefore, it is necessary to select circuit board manufacturers with reasonable prices for prototyping, provide material size or size requirements required for plate processing with manufacturers, and carry out formal PCB prototyping after communication and negotiation between both parties. It is to lay a good foundation for better cooperation between the two sides in the later stage.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve