- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In today’s manufacturing landscape, Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) play pivotal roles in streamlining the design and production processes. Together, they enhance efficiency, precision, and creativity, making them essential tools in various industries, from automotive to aerospace to consumer goods. This blog explores what CAD and CAM are, how they work together, and their benefits to modern manufacturing.

Computer-Aided Design (CAD) refers to software applications that enable designers and engineers to create, modify, analyze, and optimize designs. CAD systems can produce both 2D drawings and 3D models, providing a detailed representation of the final product. Key features of CAD include:

Design Visualization: CAD allows for detailed visualization of products before they are manufactured, enabling designers to spot potential issues and make adjustments early in the process.

Precision and Accuracy: CAD software enhances accuracy in measurements and dimensions, which is crucial for ensuring parts fit together correctly.

Simulation and Analysis: Many CAD programs offer simulation capabilities, allowing users to test how designs will perform under various conditions, thereby reducing the need for physical prototypes.

Computer-Aided Manufacturing (CAM) involves the use of software and computer-controlled machinery to automate the manufacturing process. CAM translates CAD designs into machine instructions, guiding the fabrication of components with precision. Key features of CAM include:

Automated Manufacturing: CAM systems automate various manufacturing processes, such as milling, turning, and drilling, increasing production speed and consistency.

Toolpath Generation: CAM software generates toolpaths that dictate how machinery should move to produce the desired shape and features of the component.

Integration with CNC Machines: CAM is closely integrated with Computer Numerical Control (CNC) machines, allowing for seamless transitions from design to production.

The synergy between CAD and CAM is fundamental to modern manufacturing. Here’s how they work together:

Design to Production: Designers use CAD software to create detailed models, which are then exported to CAM software. This transition eliminates errors that can occur when manually interpreting designs for manufacturing.

Streamlined Workflow: By integrating CAD and CAM, manufacturers can create a more streamlined workflow. Adjustments made in the CAD model are automatically reflected in the CAM system, facilitating rapid prototyping and iterations.

Enhanced Collaboration: The integration fosters better communication between design and manufacturing teams, ensuring that everyone is on the same page regarding product specifications and requirements.

The adoption of CAD and CAM technologies brings numerous advantages to manufacturers:

Increased Efficiency: Automation reduces manual intervention, speeding up the production process and allowing for higher output rates.

Cost Reduction: By minimizing errors and waste, CAD and CAM contribute to significant cost savings in both design and manufacturing phases.

Improved Quality: Enhanced precision and the ability to simulate designs lead to higher-quality products, reducing the likelihood of defects.

Flexibility and Customization: CAD and CAM systems enable manufacturers to quickly adapt designs for customization, allowing for tailored products that meet specific customer needs.

Shorter Time-to-Market: The streamlined workflow facilitated by CAD and CAM technologies helps reduce the time required to bring products to market, giving companies a competitive edge.

CAD and CAM are transformative technologies that have reshaped the manufacturing industry. By enabling detailed design, precise production, and efficient workflows, they allow manufacturers to produce high-quality products while reducing costs and time. As technology continues to evolve, the integration of CAD and CAM will likely deepen, offering even greater innovations and opportunities in the world of manufacturing. Understanding these tools and their capabilities is essential for any organization looking to stay competitive in today’s fast-paced market.

Make Your PCB Dreams a Reality with XPCB Limited

XPCB Limited is your go-to partner for turning your PCB dreams into reality. Our streamlined PCB manufacturing process, combined with quick-turnaround prototyping and turnkey PCBA services, ensures that your projects come to life with ease. Trust in our expertise and dedication to quality as we help you achieve your PCB goals. Join us and experience the difference with XPCB Limited.

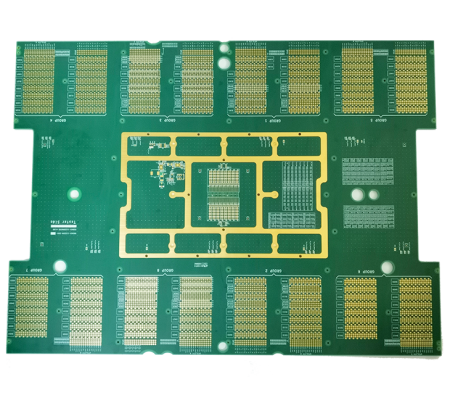

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

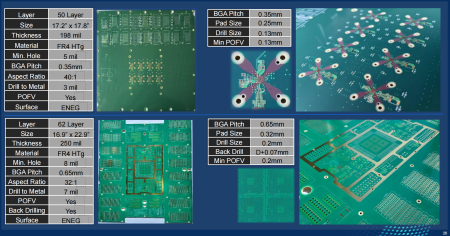

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve