- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

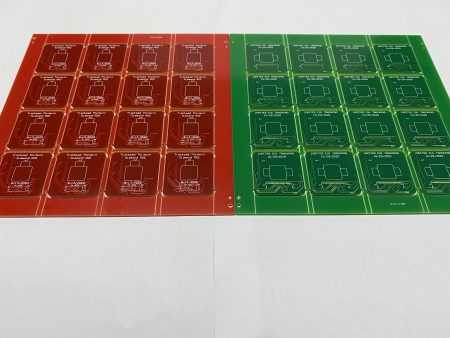

What are the causes of PCB solder mask ink shedding?

What is PCB solder mask ink refers to which layer of surface ink color is printed on the surface of the PCB board, in the process of circuit board customization. Many PCB solder masks are falling off, for example, in the production process, due to the solder mask thickness being too small, the impact of the chemical on the solder mask will lead to the local solder mask falling off. When the thickness of the line reaches more than one ounce, the solder mask is easy to fall off at the edge of the line due to the presence of a certain slope.

In addition, the following three aspects will also cause the PCB solder mask ink to fall off!

1. Before printing ink, the pre-process treatment is not in place, or the production equipment fails to carefully clean up the impurities, or there are stains and dust on the surface of the PCB circuit board, or some areas of the circuit board are oxidized due to improper operation of the pre-processing.

2. The circuit board needs to be baked at high temperatures after printing solder mask ink, such as baking the circuit board for too short a time or the temperature in the oven is not enough, which will also lead to the appearance of solder mask ink falling off.

3. The quality of the ink itself, and the use of substandard or expired ink, will also cause the ink of the PCB board to fall when it passes through the tin pot. When the PCB substrate does not match the solder mask, the hot air leveling is too much tin, the temperature of the tin liquid or the preheating temperature is too high and the number of times of soldering will also cause the PCB pad to fall off.

.

Under normal use, the double-sided pad falls off is higher than that of the single-sided side, and the multi-layer board has a large area of paving, the heat dissipation is fast, and the temperature required during soldering is also high. So the phenomenon of the pad falling off is much lower than that of the double-sided board, and the reasons for the pad falling off in the subsequent patch soldering process include:

1: Repeatedly soldering a point will solder the pad off;

2: The temperature of the soldering iron is too high, and it is easy to solder the pad off;

3: If the pressure exerted by the soldering iron tip on the pad is too large and the soldering time is too long, the pad will be soldered off;

Analysis of the causes of falling off: during the use of the circuit board, the pads often fall off, especially when the circuit board is reworked, and the pads are very easy to fall off when using the electric soldering iron. In this article, we will analyze the causes of pad detachment and take corresponding countermeasures against the causes.

In view of the fact that the pad is easy to fall off under the condition of use, the following aspects are taken:

As much as possible, the number of welding resistance of circuit board pads is increzased to meet the needs of customers. In order to improve the solderability of PCBA pads, prevent pads from falling off, improve the soldering process, and improve the soldering level of employees.

Finally, it should be emphasized that the selection of PCB substrate is the main reason that directly affects the fall off of PCB solder mask ink, and the glass fiber cloth material selection and pressing process of genuine copper clad laminate can ensure that the solder resistance of the manufactured circuit board meets the requirements of customers, and desiccant will be placed before packaging and leaving the factory to keep the circuit board always in a dry state.

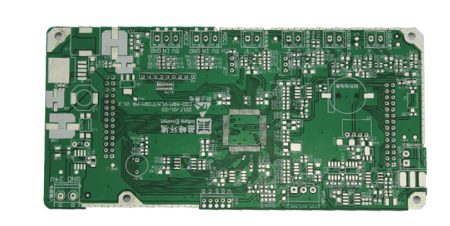

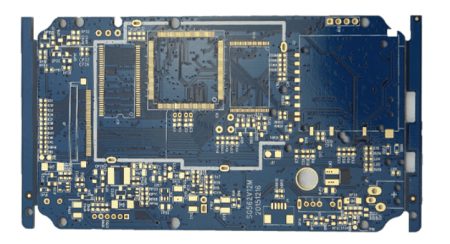

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve