- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

These are fast-changing times. In addition to creativity and design ability, today’s designers face a number of constraints as they face an increasing number of increasingly complex designs — a series of peripherals connected via IO. Moreover, today’s designs increasingly seek to make products smaller, cheaper and faster, ESPECIALLY in the mobile device market.

In recent years, a large number of high-performance, multifunctional equipment emerge endlessly, the market development is particularly rapid, so smart consumers dizzying. Bringing these types of products to the electronic design market requires a tight design process, which often involves high-density electronic circuits, as well as consideration of reducing manufacturing time and cost.

One solution to help designers and design teams meet these challenges is to adopt a combination of rigid and flex design techniques, it is Rigid-Flex PCB. Although this is not the latest technology, a combination of factors suggests that this technology is universal and can reduce costs.

From the traditional rigid PCB connected by cable, to the current Rigid-Flex board technology, from the perspective of cost, it is feasible for short term design to connect two Rigid boards with flexible cable. But this requires connectors on each board, which need to be attached to the circuit board and cables — all of which add to the cost. In addition, the rigid PCB of cable connection is prone to electrodeficiency welding, which will lead to the occurrence of faults. In contrast, Rigid-Flex PCB circuits eliminate these virtual solder joints, making them more reliable and providing higher overall product quality.

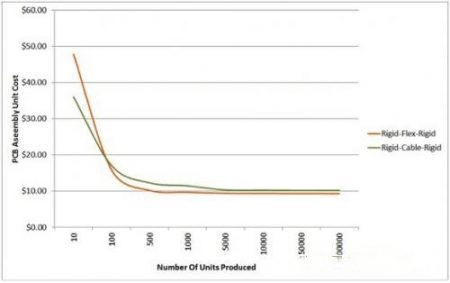

Let’s take a closer look at the total cost. Compares the simulation manufacturing cost of a rigid PCB using a traditional cable connection and a 3D Rigid-Flex design.

The traditional design is composed of rigid plates using flexible cables and connectors, while the combined design is embedded in the Rigid and soft plates with two built-in soft layers in the middle. The overall structure is a group of four printed circuit boards. Manufacturing costs for both designs are based on quotations from PCB manufacturers, including assembly costs. Add to this the cost of two separate 4 layer circuit boards, connectors, and cables that are part of the traditional design.

As can be seen from the figure, when the number of manufacturing is more than 100 sets, compared with the traditional design scheme, Rigid-Flex design will save more time and increase efficiency. This is mainly because the Rigid-Flex circuit board does not contain any connector/cables assemblies and does not require a connector assembly. Not only that, they have reliable performance and excellent workmanship. And that’s just the tip of the iceberg.

With Rigid-Flex PCB technology, designers do not need connectors, wires and cables to interconnect multiple PCBs in a single package. Because the Rigid-Flex PCB does not require cable assembly, overall assembly consumption and test complexity are reduced, both of which help to reduce costs. In addition, fewer components need to be purchased, which reduces the bill of materials, thus reducing supply chain risk and costs. Rigid-Flex PCB makes the maintenance of the product more convenient and saves the cost throughout the product life cycle.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve